| Place Of Origin: | Shenzhen, China | Certification: | ISO9001, ISO14001, ISO13485, And IATF16949 |

| Board Thickness: | 0.8-2.0 Mm | Number Of Layers: | 4 - 16 Layers |

| Copper Thickness: | 1-3 Oz/Sq Ft | Dielectric ConstantDielectric Constant: | 3.5 - 4.5 |

| Insulation Resistance: | ≥1000M0 | Voltage Withstand: | 1000 -5000 V |

| Temperature Range: | -40°C-85°C | Component Tolerance: | +0.1 -+0.5 Mm |

| Detection Method: | AOI (Automated Optical Inspection), X - RayInspection, Functional Test | Reliability Test: | Aging Test, Vibration Test, Shock Test |

| Packaging Details: | Vacuum Packing | Supply Ability: | 50000miPer Week |

| Highlight: | Ceramic Medical Equipment PCBA, IATF16949 Medical Equipment PCBA, IATF16949 ceramic circuit board | ||

-

🧪 Diagnostic Devices

MRI, CT scanners, portable diagnostic tools -

❤️ Therapeutic Equipment

Infusion pumps, ventilators, defibrillators -

⌚ Wearable Health Devices

Smartwatches, fitness & health monitoring devices -

🔬 Laboratory Instruments

Blood analyzers, centrifuges, spectrophotometers

Key Challenges in Medical PCBA Manufacturing

🛡 1. Stringent Quality & Regulatory Standards

-

ISO 13485 / IATF 16949 / IPC Class 3

-

Full traceability & zero-defect requirements

How Ring PCB Solves It:

-

✅ Certified medical-grade production facility

-

🔍 AOI / X-ray / ICT / Functional testing

-

📄 Complete batch traceability documentation

🧩 2. High-Density & Miniaturized PCB Designs

-

Fine-pitch components

-

Microvias & multilayer stack-ups

-

HDI & ceramic PCB support

Medical Equipment PCBA Technical Parameters

| Parameter | Specification |

|---|---|

| Assembly Process | SMT, THT |

| Board Thickness | 0.8 – 2.0 mm |

| Layers | 4 – 16 Layers |

| Copper Thickness | 1 – 3 oz |

| Dielectric Constant | 3.5 – 4.5 |

| Insulation Resistance | ≥1000 MΩ |

| Withstand Voltage | 1000 – 5000 V |

| Operating Temperature | -40℃ to +85℃ |

| Humidity Range | 10% – 90% |

| Component Tolerance | ±0.1 – ±0.5 mm |

| Inspection Methods | AOI, X-ray, Functional Test |

| Reliability Testing | Aging, Vibration, Shock Tests |

📌 All parameters can be customized based on project requirements.

Why Choose Ring PCB for Medical PCBA?

17+ Years Manufacturing Experience

Self-Owned Factory | Full Turnkey Support

⚙ Core Advantage 1: Advanced Engineering & Precision Manufacturing

-

🧬 2–48 layer HDI PCBs

-

📐 3/3mil trace & spacing, ±7% impedance control

-

🏗 IPC-6012 Class 3 standards

Core Advantage 2: One-Stop PCBA Turnkey Services

-

🧾 PCB fabrication + component sourcing

-

🤖 SMT assembly + functional testing

-

🛠 DFM / DFA optimization support

Core Advantage 3: Full Supply Chain Control

-

🏠 Self-owned Shenzhen factory

-

🔍 Triple QA system (AOI + impedance + thermal cycling)

-

📉 Defect rate < 0.2%

Advanced SMT & Soldering Capability

-

🤖 Samsung high-speed SMT machines

-

♻ 8-stage lead-free reflow soldering

-

🌱 RoHS compliant processes

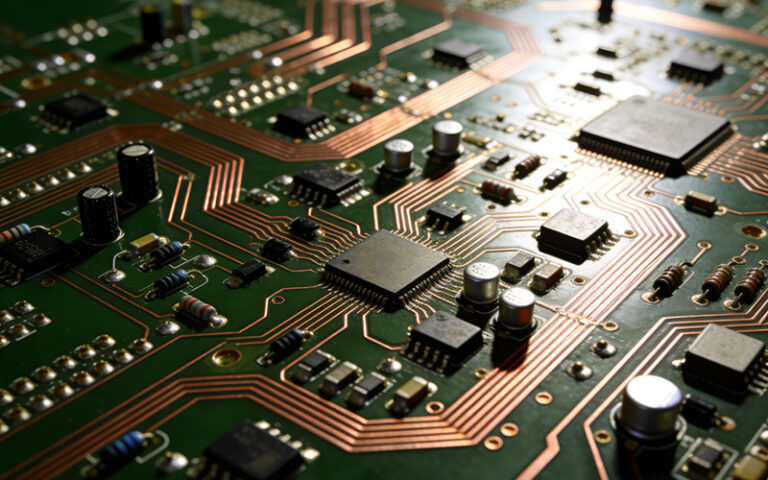

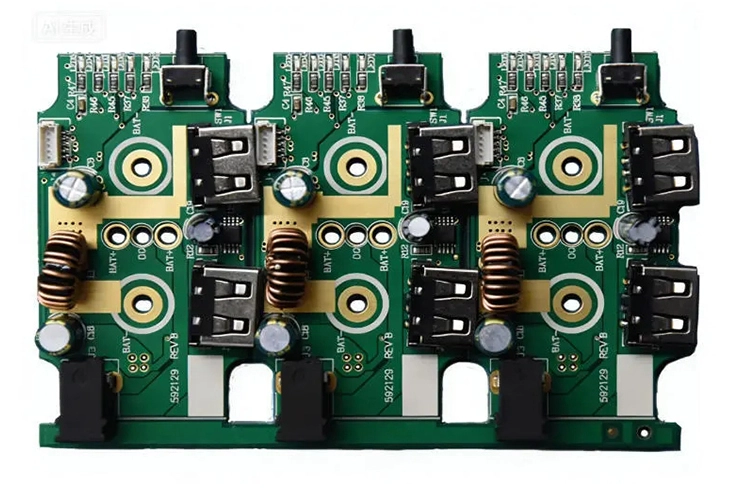

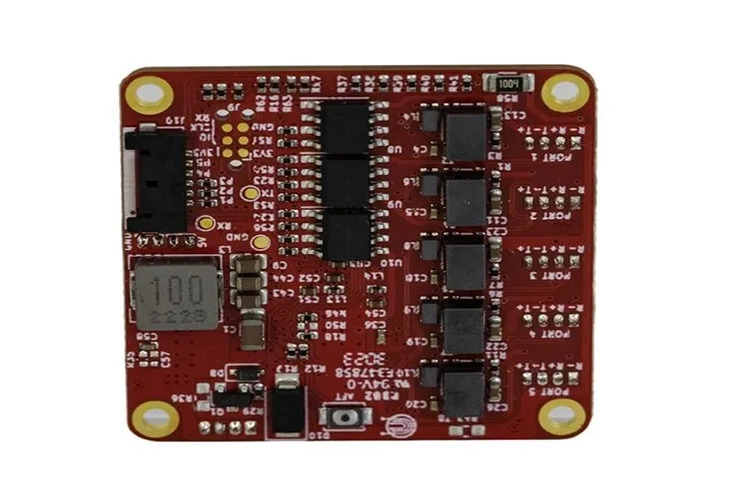

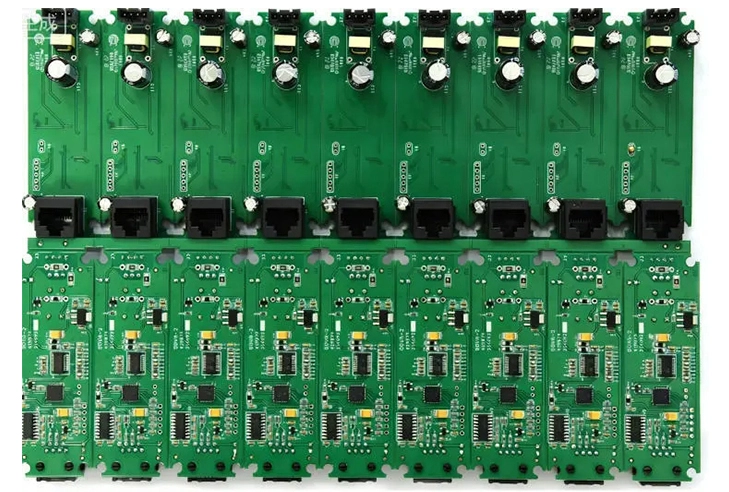

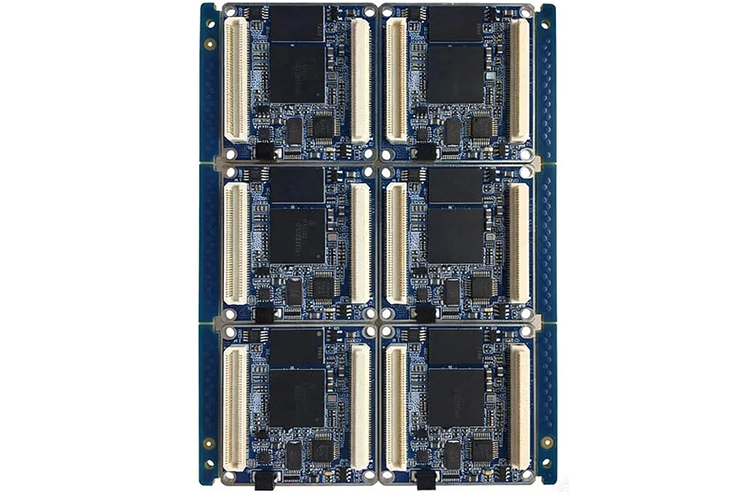

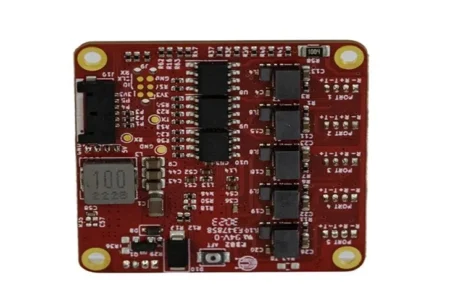

Customized Medical PCBA Samples

(All images are real customized products manufactured by Ring PCB)

Important Notes

-

📝 All products are customized services

-

📞 Please contact us before placing an order

-

🎨 Minor color differences may occur due to photography and display settings

Contact Us

📧 Email: rfq@ringpcb.com