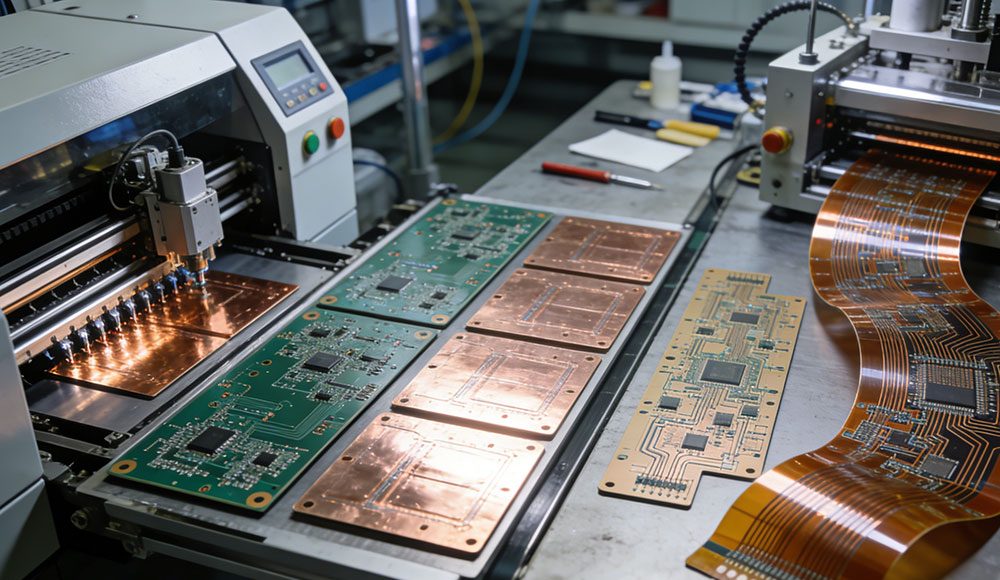

As the electronics industry continues to evolve, the demand for compact, lightweight, and high-performance electronic devices is increasing rapidly. This trend has driven major innovation in PCB manufacturing and PCB assembly, particularly with the growing adoption of Rigid Flex PCBs.

By combining rigid and flexible circuit technologies into a single structure, Rigid Flex PCBs provide enhanced design freedom, improved reliability, and efficient space utilization—making them a critical solution for modern electronic applications.

The Rise of Rigid Flex PCBs in PCB Manufacturing

Traditional PCB manufacturing typically relies on either rigid PCBs or flexible PCBs. However, many modern applications—ranging from consumer electronics to medical devices and aerospace systems—require both structural stability and flexibility within the same design.

Rigid Flex PCBs address this challenge by integrating rigid sections for component mounting with flexible areas for bending and folding, all within one unified board. This hybrid structure eliminates the need for multiple boards, connectors, and cables.

Compared with conventional PCB designs, Rigid Flex PCBs significantly reduce interconnections, which lowers assembly complexity, minimizes signal loss, and improves overall mechanical reliability. As a result, PCB fabrication becomes more streamlined while maintaining high performance standards.

Benefits Across the PCB Fabrication and Assembly Lifecycle

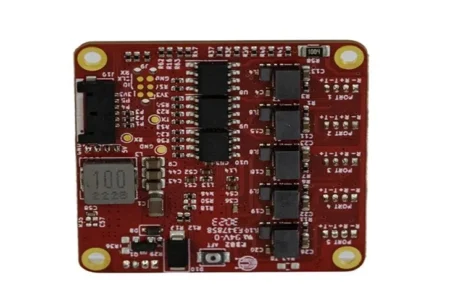

Rigid Flex technology fundamentally changes how engineers approach PCB fabrication and PCB assembly.

From a design perspective, Rigid Flex PCBs allow for three-dimensional layouts that fit into tight or irregular spaces—something traditional rigid boards cannot achieve. This flexibility enables innovative product designs without sacrificing durability.

During PCB assembly, fewer connectors and solder joints mean:

-

Lower risk of connection failure

-

Improved vibration and shock resistance

-

Higher long-term reliability

Additionally, reduced part count simplifies testing and debugging processes. Engineers can access components more easily, leading to shorter development cycles and faster product iteration—a critical advantage in competitive markets.

Although initial fabrication may be more complex, Rigid Flex PCBs often deliver long-term cost savings by reducing assembly labor, improving yield rates, and lowering maintenance requirements.

Applications Driving Demand for Rigid Flex PCBs

Once limited to high-end or specialized markets, Rigid Flex PCBs are now widely adopted across multiple industries, including:

-

Wearable electronics and smart devices

-

Automotive control and infotainment systems

-

Medical imaging and monitoring equipment

-

Aerospace and military communication systems

In each of these applications, Rigid Flex PCBs offer an ideal balance of lightweight construction, compact design, and high electrical performance, making them essential to next-generation electronic products.

Why Choosing the Right PCB Fabrication Manufacturer Matters

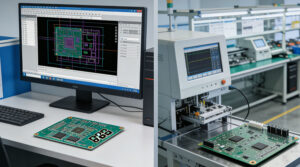

Producing Rigid Flex PCBs requires advanced manufacturing expertise, strict process control, and a deep understanding of materials and assembly techniques. Selecting an experienced PCB fabrication manufacturer is therefore critical to project success.

Ring PCB, established in 2008, is a professional enterprise specializing in PCB manufacturing, PCB assembly, and customized PCB solutions. With 18 years of industry experience, a skilled team of 500 employees, and a 10,000-square-meter modern in-house PCB factory in Shenzhen, China, Ring PCB delivers reliable, high-quality products that comply with international standards.

Ring PCB supports 3-day rapid PCB prototyping and 7-day batch production, exporting products to over 50 countries and regions. The company offers flexible order quantities, full-turnkey PCB assembly services, and customized solutions for both small and large-scale projects.

Whether developing a new IoT device or upgrading a military-grade system, Ring PCB helps customers navigate the complexities of Rigid Flex PCB design, fabrication, and assembly, ensuring performance, reliability, and compliance at every stage.

Final Thoughts

As electronic products become smaller, smarter, and more integrated, Rigid Flex PCBs will continue to play a crucial role in advancing PCB manufacturing and assembly. Their ability to combine flexibility, durability, and high performance makes them a cornerstone of modern electronic design.

To ensure success from prototyping to mass production, partnering with a trusted PCB fabrication manufacturer that offers full-turnkey services is essential.

Contact Us

📧 Email: rfq@ringpcb.com