| Place Of Origin: | Shenzhen, China | Certification: | ISO9001, ISO14001, ISO13485, and IATF16949. |

| Surface Finish: | ENIG (Electroless Nickel Immersion Gold), HASL (Hot - Air Solder Leveling), Etc. | Operating Temperature: | -40°C - 85°C |

| Number Of Layers: | From 2 - Up To 48 Layers | Certifications: | IPC, RoHS, UL, ISO9001, ISO14001,ISO13485,IATF16949 |

| Testing And Inspection: | Automated Optical Inspection (AOI), X-ray Inspection | Assembly Accuracy: | Tolerance Within ±0.05 - 0.1mm For Component Placement |

| Other Service: | We Can Help With The Procurement Of Electronic Components On Behalf Of Customers. | Cost Efficiency: | Competitive Pricing And Cost Reduction Strategies |

| Environmental Responsibility: | Sustainable Practices And Green Initiatives | Customization: | Tailored Solutions To Meet Customer's Specific Requirements |

| Manufacturing Capabilities: | PCB Assembly, Box Build Assembly, Cable And Wire Harness Assembly, Testing And Inspection | Quick Turnaround Time: | Rapid Prototyping And Fast Production Lead Times |

| Flexibility: | Ability To Handle Small To Large Production Volumes | Packaging Details: | Vacuum packing+Cardboard packing case |

| Supply Ability: | 50000㎡per week | ||

| Highlight: | 4 layer PTFE FR4 multilayer PCB, industrial medical RF multilayer PCB, PTFE FR4 PCB manufacturing | ||

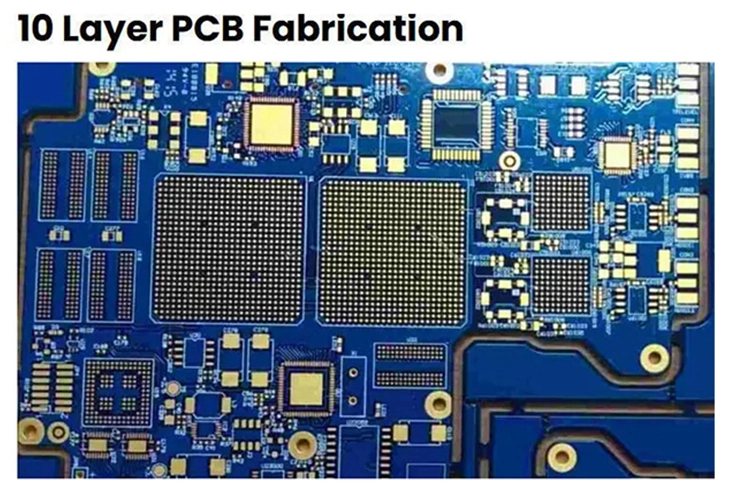

Multilayer PCB Manufacturing & One-Stop PCB and PCBA Services

Multilayer PCB manufacturing refers to the fabrication of printed circuit boards consisting of multiple conductive copper layers laminated together with insulating materials. These multilayer PCBs are widely used in industrial electronics, medical devices, RF communication systems, automotive electronics, and other applications that require high reliability, stable signal transmission, and precise electrical performance.

At Ring PCB, we specialize in professional multilayer PCB manufacturing and one-stop PCB & PCBA services. Based on customer-provided Gerber files, drawings, and technical specifications, our experienced engineering and production teams ensure accurate fabrication, strict process control, and consistent product quality from prototype to mass production.

🔹 Product Features & Advantages

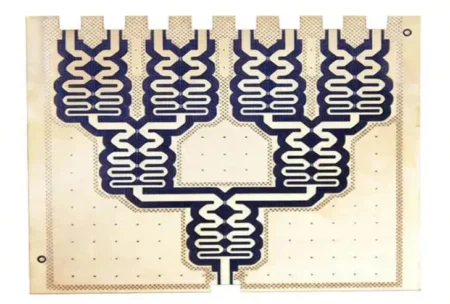

PTFE + FR4 Mixed-Material Multilayer PCB Structure

This 4-layer multilayer PCB adopts a PTFE + FR4 hybrid material structure, which is commonly used in high-frequency, industrial, and medical electronic applications where both electrical performance and mechanical stability are required.

-

PTFE layers support low dielectric constant and low-loss signal transmission, ideal for RF and high-frequency circuits

-

FR4 layers provide excellent mechanical strength, thermal stability, and cost efficiency

-

Suitable for harsh and demanding environments requiring long-term electrical stability

This mixed-material structure demonstrates Ring PCB’s advanced capability in high-frequency multilayer printed circuit board manufacturing.

🔹 Customized PCB Manufacturing Example

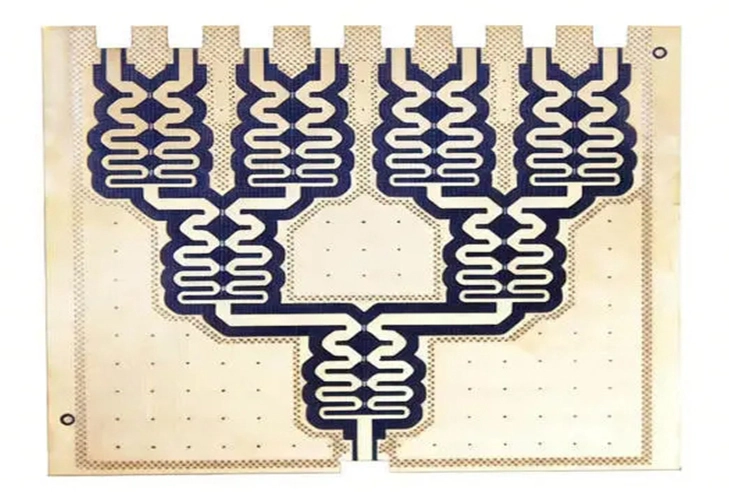

Below is a photo of a customized 4-layer PTFE and FR4 multilayer PCB manufactured by Ring PCB for our client, showcasing precise lamination, clean edge plating, and high-quality surface finishing.

🔹 Common Technical Parameters (Reference)

| Item | Specification |

|---|---|

| PCB Type | Multilayer Printed Circuit Board |

| Layer Count | 4 Layers |

| Base Materials | PTFE + FR4 (Mixed Material) |

| Board Thickness | 1.6 mm |

| Surface Finish | Immersion Gold (ENIG) |

| Special Process | Mixed Material Lamination, Edge Plating |

| Typical Applications | Industrial, Medical, RF, High-Frequency Electronics |

Note:

The above specifications are for reference only. Actual PCB parameters can be fully customized according to customer drawings, Gerber files, and application requirements.

For detailed technical consultation and manufacturing feasibility evaluation, please contact Ring PCB’s professional sales and engineering team.

Contact Us

📧 Email: rfq@ringpcb.com