| Place Of Origin: | Shenzhen, China | Certification: | ISO9001, ISO14001, ISO13485, And IATF16949 |

| Type: | IoT PCB Assembly | Layer Count: | 1-40 Layers (standard: 2-16 Layers) |

| Copper Thickness: | 0.5-14 Oz (17.5-490μm); 1-3 Oz Typical For IoT. | Minimum Line/Space: | 2.5/2.5 Mil (0.0635mm) For HDI |

| Material Options: | R-4 (Tg 130-170°C), Rogers RO4003C (Dk=3.38), And Aluminum Cores | Surface Finishes: | ENIG, OSP, HASL (lead-free), And Gold Plating |

| Operating Temperature: | -40°C To +125°C (industrial Grade) | Certifications: | IPC, RoHS, UL, ISO9001, ISO14001,ISO13485,IATF16949 |

| Other Service: | We Can Help With The Procurement Of Electronic Components On Behalf Of Customers. | Packaging Details: | Vacuum packing+Cardboard packing case |

| Supply Ability: | 50000㎡per week | ||

| Highlight: | IoT PCBA manufacturing for smart homes, PCB assembly for home monitoring systems, smart home PCBA with warranty | ||

Product Description

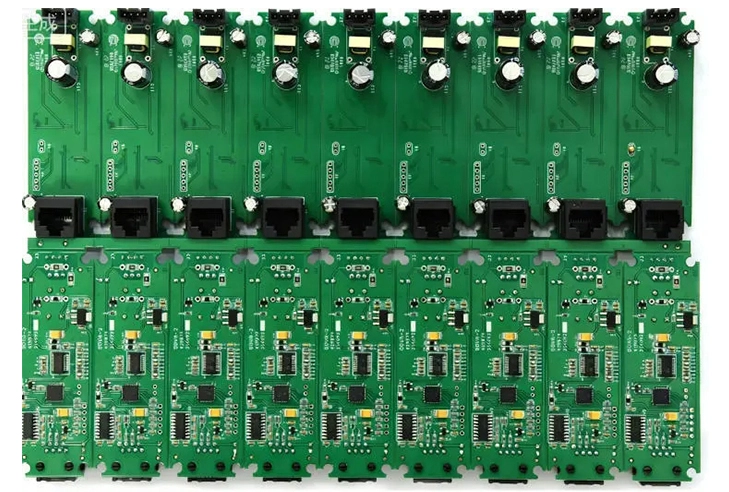

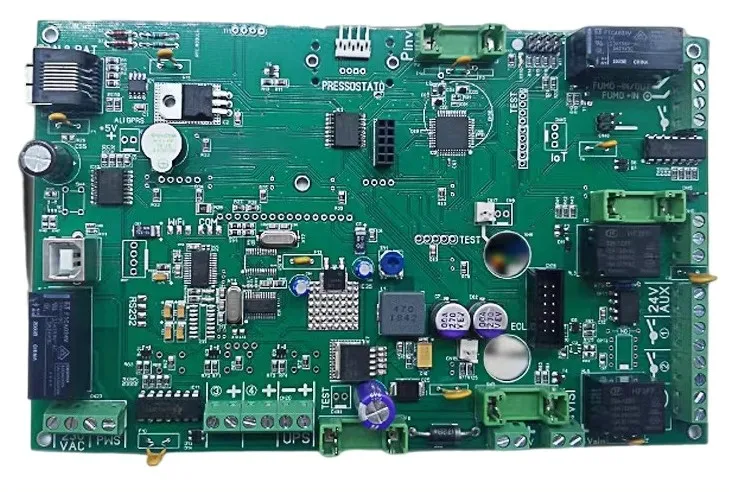

Custom IoT PCBA Manufacturing & Full Turnkey Assembly for Smart Home Devices

Ring PCB is a professional manufacturer specializing in IoT PCBA fabrication and turnkey assembly for smart home monitoring systems. With 17 years of experience, we provide high-frequency, low-power, and miniaturized PCB solutions for smart locks, HVAC controllers, voice assistants, security sensors, and IoT gateways.

Our Shenzhen and Zhuhai factories cover over 5,000㎡ and are staffed with 500 skilled professionals, delivering fast prototyping (3 days) and mass production (7 days) worldwide.

IoT PCBA Product Features

-

High-Frequency Signal Integrity:

Supports 5G, Wi-Fi 6E, Bluetooth 5.3 with precise impedance control using low-loss materials like Rogers RO4003C. -

Ultra-Low Power Consumption:

Optimized for battery-powered devices with PMICs and sleep-mode circuits (standby <8μA). -

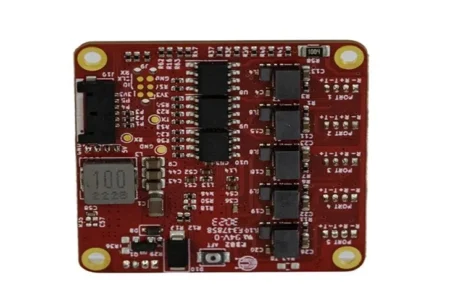

Miniaturization & High-Density Layouts:

Integrates 01005/0201 passive components, system-in-package (SiP), and HDI design for compact layouts. -

Flexible & Rigid-Flex Design:

Combines rigid FR-4 and flexible polyimide for curved or wearable devices. -

Thermal Management:

Copper cladding and heat spreaders reduce hotspot temperatures by 15–30%. -

Environmental Resilience:

3D coating and RoHS-compliant materials resist UV, salt fog, and extreme temperatures.

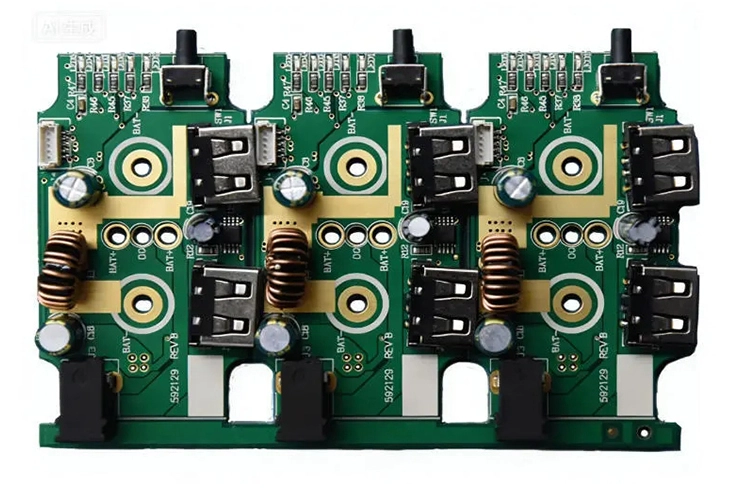

Advantages of IoT PCB Assembly

-

Rapid Time-to-Market:

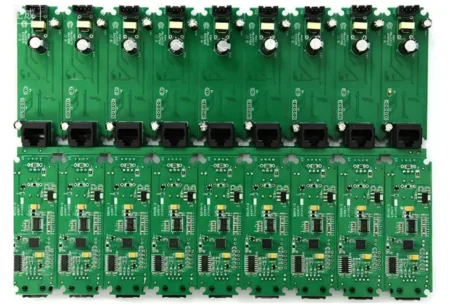

Flexible manufacturing enables 3-month iteration cycles, 10-minute small-batch changeovers. -

Cost-Effective Scalability:

Modular production supports 100–100,000 units without large-volume penalties. -

Signal Reliability:

Hybrid stack-up with controlled impedance ensures <5% signal loss in 5G/mmWave applications. -

Green Manufacturing:

ENIG/OSP finishes and halogen-free materials comply with EU environmental standards. -

Multi-Domain Compatibility:

Simultaneous operation of sensors, RF modules, and microcontrollers with EMI shielding.

Technical Challenges & Ring PCB Solutions

| Challenge | Ring PCB Solution |

|---|---|

| Precision Soldering | SPI 3D solder paste inspection + AOI + X-ray, <5% voiding in BGA joints |

| High-Frequency Layout | Millimeter-wave routing <10μm linewidth; hybrid laminates (Megtron 6 + Rogers) |

| Thermal Expansion | Manage CTE mismatch between copper & FR-4 to avoid delamination |

| EMC Compliance | Ground planes and differential pairs minimize interference |

| Material Selection | Optimize Dk vs. cost: Rogers RO4003C (3.38) vs. standard FR-4 (4.4) |

Application Areas of IoT PCBA

| Industry | Use Cases |

|---|---|

| Smart Home | Smart locks, HVAC controllers, voice assistants (<10μA standby) |

| Industrial IoT | Predictive maintenance sensors, PLCs, robotics |

| Healthcare | Wearable health monitors (ECG, glucose) with biocompatibility |

| Logistics | Asset trackers (GPS + LoRa) for cold chain management |

| Agriculture | Soil moisture sensors, drone-based crop monitoring |

| Automotive | Telematics (T-BOX), ADAS modules (-40°C to 125°C) |

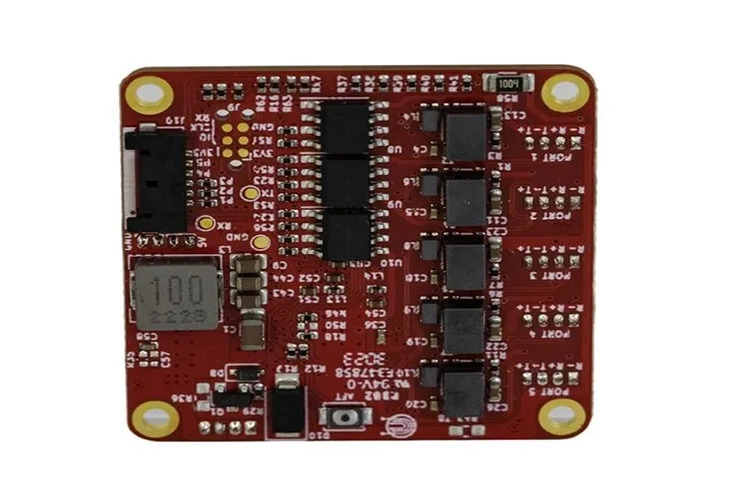

Technical Parameters

| Parameter | Specification |

|---|---|

| Layer Count | 1–40 layers (standard: 2–16) |

| Copper Thickness | 0.5–14 oz (1–3 oz typical for IoT) |

| Min. Line/Space | 2.5/2.5 mil (0.0635mm) for HDI |

| Microvia Diameter | 0.08–0.15 mm (stacked/buried) |

| Material Options | FR-4 (Tg 130–170°C), Rogers RO4003C, Aluminum cores |

| Inspection | AOI, X-ray (BGA void analysis), ICT |

| Surface Finish | ENIG, OSP, HASL (lead-free), gold plating |

| Thermal Resistance | <10°C/W with 0.1mm copper cladding |

| RoHS Compliance | Halogen-free, lead-free, REACH-certified |

| Operating Temp | -40°C to +125°C (industrial grade) |

Note: Custom IoT PCBAs available. Contact our customer service for specific requirements.

Why Choose Ring PCB?

1. Direct Factory Pricing & Transparent Manufacturing

-

Self-owned Shenzhen factory ensures cost control and eliminates middlemen.

-

Factory visits welcome to see automated SMT lines and production processes.

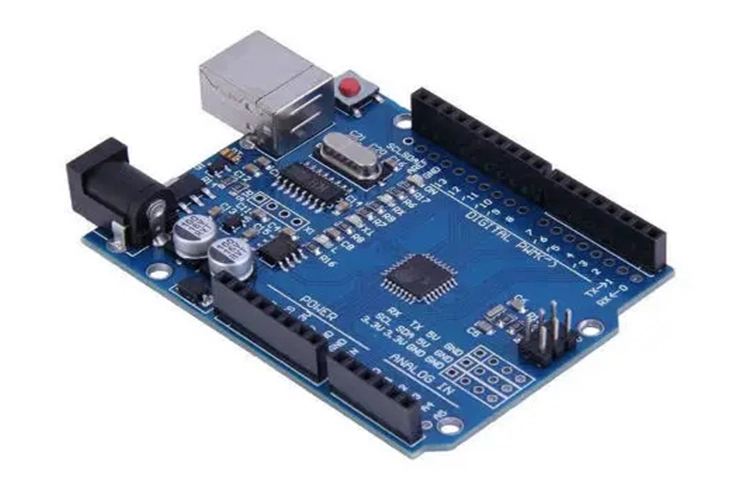

2. End-to-End One-Stop PCB & PCBA Services

-

PCB fabrication (2–48 layers), component sourcing, SMT assembly, turnkey projects.

-

17+ years of experience, 500+ skilled employees, 5,000+ electronic projects for 3,000+ global clients.

3. Stringent Quality Control

-

Multi-stage QA: SPI 3D, AOI, LCR testing, X-ray inspections for zero-defect BGA joints.

-

Certified to IPC standards, RoHS, UL, ISO 9001/14001/13485, IATF16949.

4. Industry-Leading Capabilities & Customization

-

High-frequency, heavy copper, HDI, and complex PCBAs for communication, medical, EV charging, robotics.

-

Prototype-to-mass-production support with fast turnaround via in-house factories.

5. Reliable Partner for Diverse Applications

-

Security, industrial automation, drones, servers, IoT systems.

-

Real-time QC, incoming material inspection, and on-time delivery guaranteed.

Ring PCB Turnkey Advantages

-

Convenience: One-stop service reduces supply chain complexity.

-

Quality: Certifications and multi-inspections ensure reliability.

-

Speed: In-house production for fast prototyping & delivery.

-

Cost-Effectiveness: Direct factory pricing, no quality compromise.

-

Expertise: 17+ years supporting global clients across diverse industries.

Contact Us

📧 Email: rfq@ringpcb.com