| Place Of Origin: | Shenzhen, China | Certification: | ISO9001, ISO14001, ISO13485, And IATF16949 |

| Type: | IoT PCB Assembly | Layer Count: | 1-40 Layers (standard: 2-16 Layers) |

| Copper Thickness: | 0.5-14 Oz (17.5-490μm); 1-3 Oz Typical For IoT. | Minimum Line/Space: | 2.5/2.5 Mil (0.0635mm) For HDI |

| Material Options: | R-4 (Tg 130-170°C), Rogers RO4003C (Dk=3.38), And Aluminum Cores | Surface Finishes: | ENIG, OSP, HASL (lead-free), And Gold Plating |

| Operating Temperature: | -40°C To +125°C (industrial Grade) | Certifications: | IPC, RoHS, UL, ISO9001, ISO14001,ISO13485,IATF16949 |

| Other Service: | We Can Help With The Procurement Of Electronic Components On Behalf Of Customers. | Packaging Details: | Vacuum packing+Cardboard packing case |

| Supply Ability: | 50000㎡per week | ||

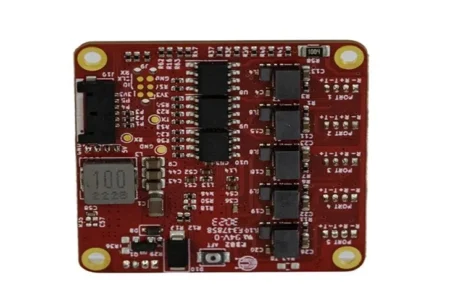

| Highlight: | IoT Device PCB Assembly Services, Smart Gadgets PCB Assembly, FR-4 PCB Assembly Services | ||

Product Description

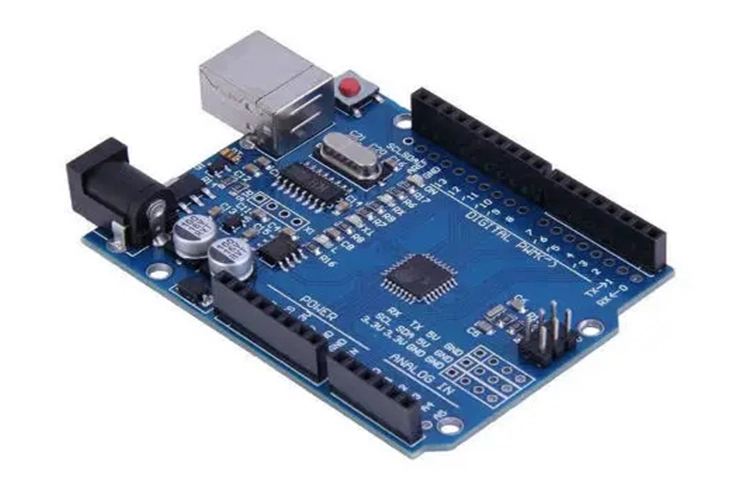

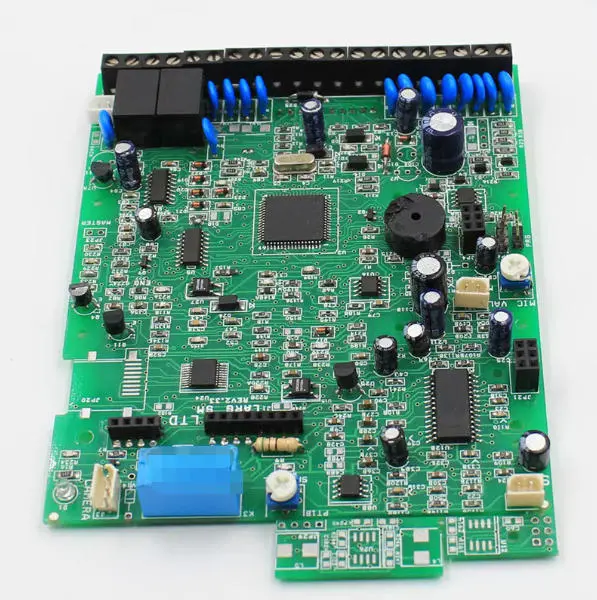

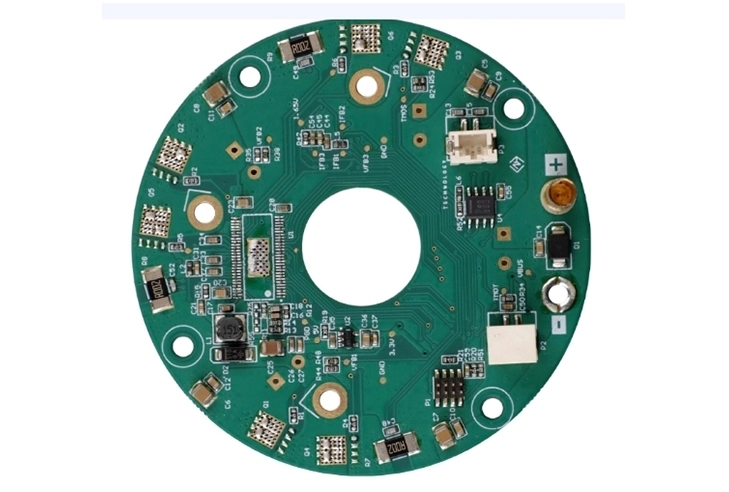

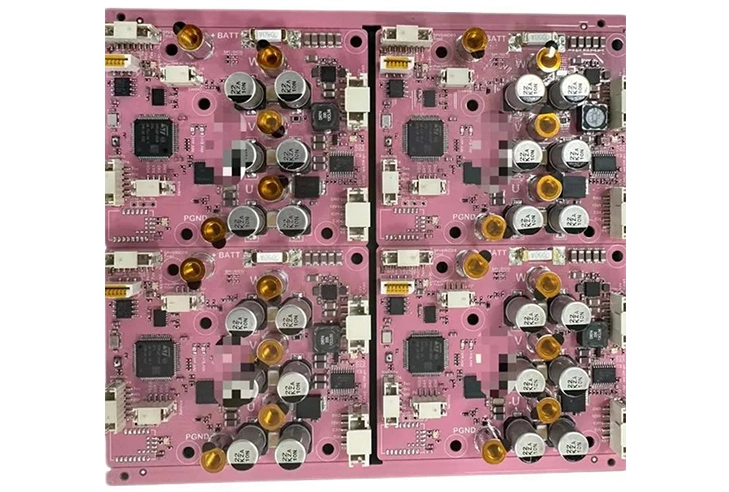

Ring PCB provides custom IoT PCB assembly services for smart gadgets and devices, featuring FR-4 PCBs (0.5-14 oz), high-frequency signal integrity, low power consumption, and full turnkey solutions. Rapid prototyping in 3 days, mass production in 7 days, serving global clients across 50+ countries.

Features of IoT PCB Assembly

-

High-Frequency Signal Integrity

Supports advanced wireless protocols (5G, Wi-Fi 6E, Bluetooth 5.3) using Rogers RO4003C and high-Tg FR-4 materials for precise impedance and minimal signal loss. -

Ultra-Low Power Consumption

Optimized for battery-powered IoT devices, with standby current as low as 8μA via power management ICs and sleep-mode circuits. -

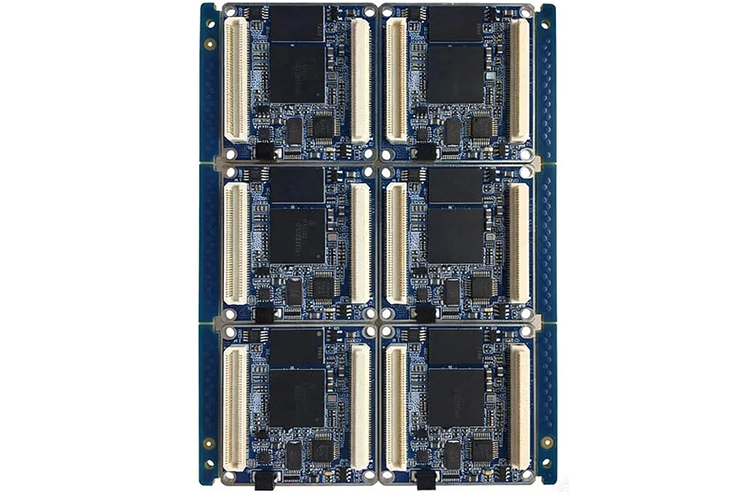

Miniaturization & High Density

Supports 01005/0201 passive components, System-in-Package (SiP), and HDI layouts for compact, high-density board designs. -

Flexible & Rigid-Flex Design

Combines rigid FR-4 and flexible polyimide layers for curved devices like smartwatches and wearables. -

Thermal Management

Copper cladding and heat spreaders reduce hotspot temperatures by 15-30%, ensuring stable operation in high-power modules. -

Environmental Resilience

RoHS-compliant 3D coatings protect against salt fog, UV, and extreme temperatures.

Advantages of IoT PCB Assembly

-

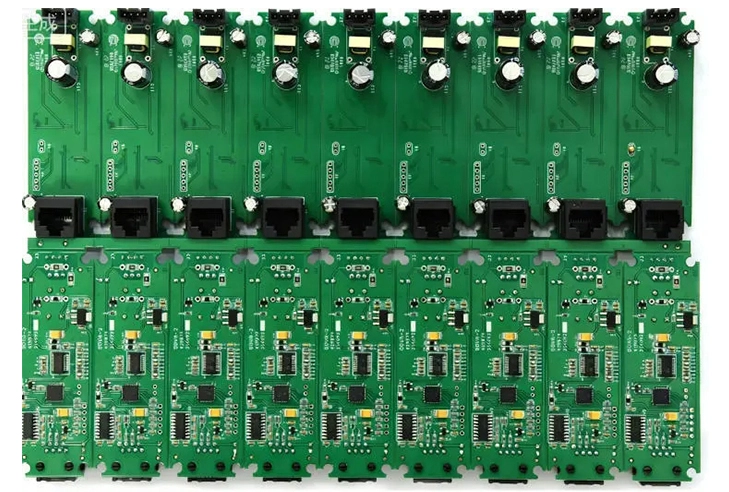

Rapid Time-to-Market – Prototype in 3 days, mass production in 7 days.

-

Cost-Effective Scalability – Efficient modular production from 100 to 100,000 units.

-

Reliable Signal Performance – Controlled impedance and hybrid stack-ups reduce signal loss <5%.

-

Green Manufacturing – ENIG/OSP finishes, halogen-free materials, EU-compliant.

-

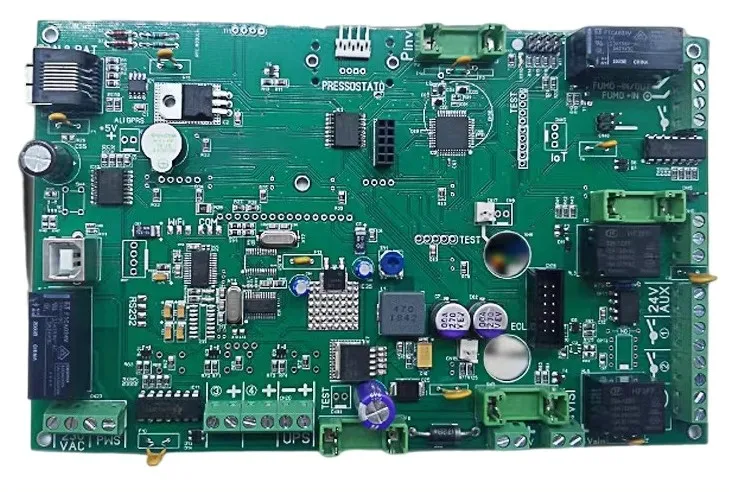

Multi-Domain Compatibility – Supports sensors, RF modules, and microcontrollers simultaneously with EMI shielding.

Technical Challenges and Solutions

| Challenge | Ring PCB Solution |

|---|---|

| Precision Soldering | SPI 3D, AOI, X-ray inspection for BGA void <5% |

| High-Frequency Layout | Millimeter-wave routing <10μm, hybrid laminates (Megtron 6 + Rogers) |

| Thermal Expansion | CTE optimization to prevent delamination in multi-layer boards |

| EMC Compliance | Ground planes & differential pairs mitigate Wi-Fi & sensor interference |

| Material Selection | Balances dielectric constant and cost: FR-4 vs Rogers RO4003C |

Application Areas

-

Smart Home – Smart locks, HVAC controllers, voice assistants (<10μA standby).

-

Industrial IoT – Predictive maintenance sensors, PLCs, robotics.

-

Healthcare – Wearable health monitors (ECG, glucose).

-

Logistics – GPS + LoRa asset trackers for cold chain.

-

Agriculture – Soil moisture sensors, drone monitoring.

-

Automotive – Telematics (T-BOX), ADAS modules (-40°C to 125°C).

Technical Parameters

| Parameter | Specification |

|---|---|

| Layer Count | 1-40 layers (standard 2-16) |

| Copper Thickness | 0.5-14 oz (17.5-490μm); 1-3 oz typical |

| Minimum Line/Space | 2.5/2.5 mil (0.0635mm) HDI |

| Microvia Diameter | 0.08-0.15mm (stacked/buried vias) |

| Material Options | FR-4, Rogers RO4003C, aluminum cores |

| Inspection Methods | AOI, X-ray, ICT |

| Surface Finishes | ENIG, OSP, HASL (lead-free), gold plating |

| Thermal Resistance | <10°C/W with 0.1mm copper |

| RoHS Compliance | Halogen-free, lead-free, REACH certified |

| Operating Temp | -40°C to +125°C |

Why Choose Ring PCB?

-

Direct Factory Pricing – Shenzhen factory ensures cost-effective source-level pricing.

-

One-Stop Turnkey Service – PCB fabrication, component sourcing, SMT assembly, testing.

-

Advanced Quality Control – SPI, AOI, LCR, X-ray; IPC, RoHS, UL, ISO, IATF16949 certified.

-

Custom Capabilities – High-frequency, heavy copper, complex PCBs; prototype to mass production.

-

Global Experience – 17+ years, 5,000+ projects, 3,000+ clients across 50+ countries.

Contact Us

📧 Email: rfq@ringpcb.com