| Place Of Origin: | Shenzhen, China | Certification: | ISO9001, ISO14001, ISO13485, And IATF16949 |

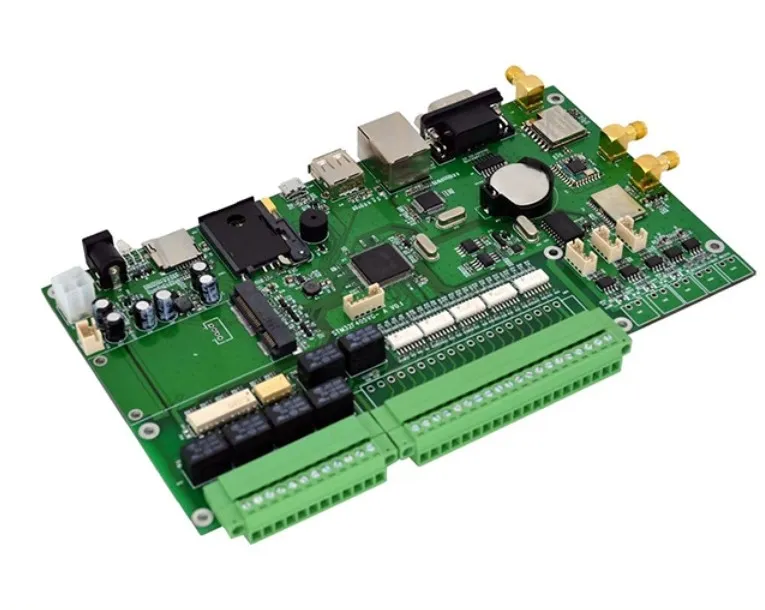

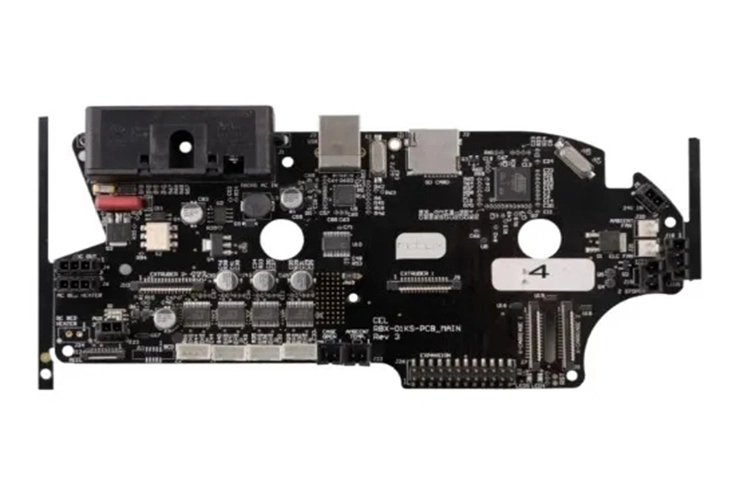

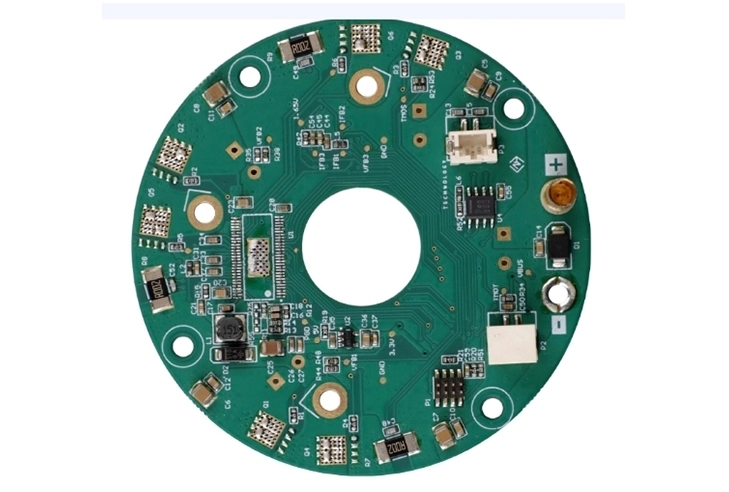

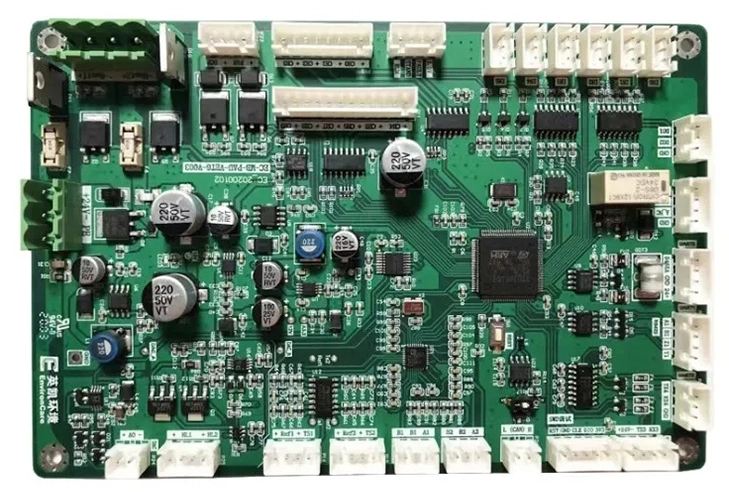

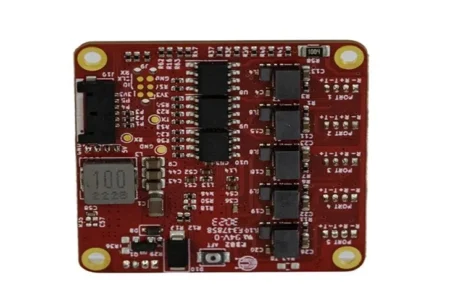

| Type: | Smart Robotics PCBA | Layer Count: | 2–30+ Layers (complexity-dependent) |

| Board Material: | FR-4 (standard), Rogers (high-frequency), Or CEM-3 For Rigidity Depends On Model | PCB Size: | Depends On Model Or Customized |

| Copper Thickness: | 1–3 Oz (2–3 Oz For High-power Applications) Depends On Model | Surface Finishes: | ENIG, HASL, OSP, Immersion Tin, Immersion Silver |

| Testing And Inspection: | Automated Optical Inspection (AOI), X-ray Inspection | Application Areas: | Fit For Cleaning Robots, Delivery Robots, And Elderly - Care Robots,ect. |

| Other Service: | We Can Help With The Procurement Of Electronic Components On Behalf Of Customers. | Packaging Details: | Vacuum packing+Cardboard packing case |

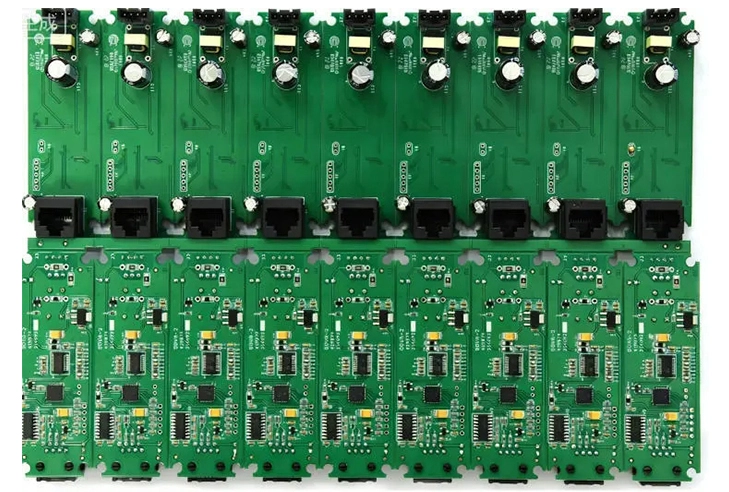

| Supply Ability: | 50000㎡per week | ||

| Highlight: | integrated led smd pcb, QFN led smd pcb, pcb integrated led Assembly | ||

Product Description

Ring PCB provides custom smart robotics PCBA with multi-language programming compatibility, high-precision assembly, and turnkey services. Ideal for industrial robots, service robots, medical robotics, aerospace, and consumer robots. Rapid prototyping, mass production, and global delivery.

Features of Smart Robotics PCBA

-

High Precision Placement

Robots in PCBA, such as pick-and-place machines, place tiny components with micron-level accuracy, ensuring reliable operation and reducing component-related failures. -

Automation-Driven Efficiency

Automated assembly lines streamline repetitive tasks like component feeding, soldering, and testing, increasing throughput and reducing labor costs. -

Intelligent Monitoring

Sensors, cameras, and data analytics provide real-time feedback to detect issues early and optimize production quality continuously. -

High Integration & Compactness

Supports high-density PCBs for small and powerful robotics devices, optimizing space utilization. -

Reliability & Stability

Advanced quality management and testing ensure components work reliably in diverse environments, extending the service life of robotic systems. -

Customizability

Tailored PCBA solutions for industrial, service, or specialized robots, meeting specific operational and functional requirements.

Key Components of Smart Robotics PCBA

-

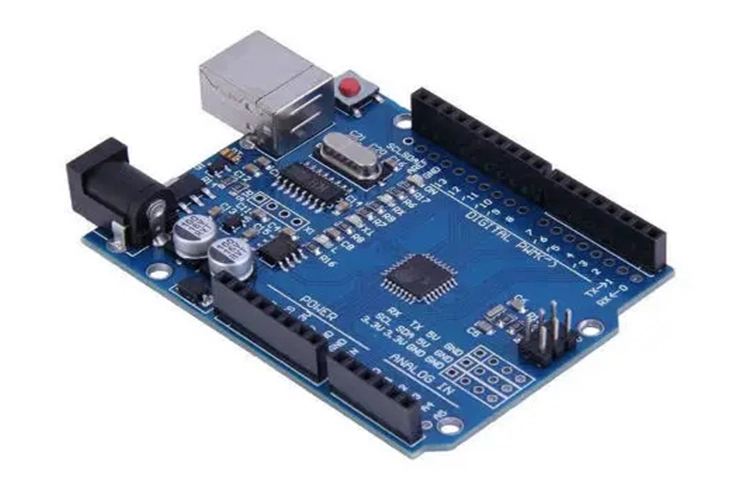

Microcontroller PCBA

-

Motion Control PCBA

-

Sensor Interface PCBA

-

Vision Sensor PCBA

-

Wireless Communication PCBA

-

Wired Communication PCBA

-

Power Management PCBA

-

Power Conversion PCBA

Note: Ring PCB customizes these modules based on your drawings or specific requirements.

Common Technical Parameters

| Parameter | Specification |

|---|---|

| Board Material | FR-4 (standard), Rogers (high-frequency), or CEM-3 |

| Layer Count | 2–30+ layers (depending on complexity) |

| Trace Width/Spacing | 0.1–0.5 mm (current & impedance adjusted) |

| Via Size | 0.3–1.0 mm (smaller for high-density PCBs) |

| Copper Thickness | 1–3 oz (2–3 oz for high-power applications) |

| Surface Finish | HASL, ENIG, OSP (ENIG preferred for harsh environments) |

| Component Footprint | SMT (0402/0603 resistors, QFP/BGA ICs) |

| Impedance Control | 50–100 Ω for high-speed signals |

| Power Distribution | Voltage regulation ±1%, ripple <50mV |

| Customizable Options | Thermal vias, EMI shielding, special packaging |

Additional specifications (thermal management, connectors, etc.) can be customized per project requirements.

Applications of Smart Robotics PCBA

-

Industrial Robots – Production line automation, material handling, soldering, spraying; precise movement control and high-load operation.

-

Service Robots – Cleaning, delivery, and elderly-care robots with navigation, obstacle avoidance, and user interaction.

-

Medical Robots – Surgical robots, diagnostic devices; high-precision PCBA ensures safe and accurate operation.

-

Aerospace & Defense – UAVs, space exploration robotic arms, and military robots; supports miniaturization and extreme environmental performance.

-

Consumer Robots – Educational and home-entertainment robots providing computing and interactive control capabilities.

Core Advantages of Ring PCB

-

Advanced Engineering & Precision PCB Manufacturing

-

High-density stack-ups (2–48 layers) with blind/buried vias, 3/3mil trace/spacing, ±7% impedance control.

-

Self-owned facility with LDI laser exposure, vacuum lamination, and flying probe testers adhering to IPC-6012 Class 3.

-

-

Integrated Turnkey PCBA Services

-

Full support: PCB fabrication, component sourcing, SMT assembly, and functional testing.

-

DFM/DFA optimization reduces design risks and BOM costs.

-

Rigorous QC: X-ray, AOI, and 100% functional testing for zero-defect delivery.

-

-

Self-Owned Factory with Full Supply Chain Control

-

Vertical integration: raw materials, production, and testing managed in-house.

-

Triple quality assurance: AOI + impedance testing + thermal cycling, defect rate <0.2%.

-

Global certifications: ISO9001, IATF16949, and RoHS compliance.

-

-

Advanced Soldering & Assembly

-

8-stage lead-free reflow and wave soldering ensure high-quality, environmentally compliant assembly.

-

-

One-Stop Service & Global Experience

-

17+ years supporting clients worldwide.

-

Custom solutions for industrial, medical, aerospace, and consumer robotics.

-

Contact Us

📧 Email: rfq@ringpcb.com