| Place Of Origin: | Shenzhen, China | Certification: | ISO9001, ISO14001, ISO13485, And IATF16949 |

| Type: | Smart Robotics PCBA | Layer Count: | 2–30+ Layers (complexity-dependent) |

| Board Material: | FR-4 (standard), Rogers (high-frequency), Or CEM-3 For Rigidity Depends On Model | PCB Size: | Depends On Model Or Customized |

| Copper Thickness: | 1–3 Oz (2–3 Oz For High-power Applications) Depends On Model | Surface Finishes: | ENIG, HASL, OSP, Immersion Tin, Immersion Silver |

| Testing And Inspection: | Automated Optical Inspection (AOI), X-ray Inspection | Application Areas: | Fit For Cleaning Robots, Delivery Robots, And Elderly - Care Robots,ect. |

| Other Service: | We Can Help With The Procurement Of Electronic Components On Behalf Of Customers. | Packaging Details: | Vacuum packing+Cardboard packing case |

| Supply Ability: | 50000㎡per week | ||

| Highlight: | Stability Smart Robotics PCB Assembly, Custom Smart Robotics PCB Assembly, Reliability Smart Robotics PCB Assembly | ||

Product Description

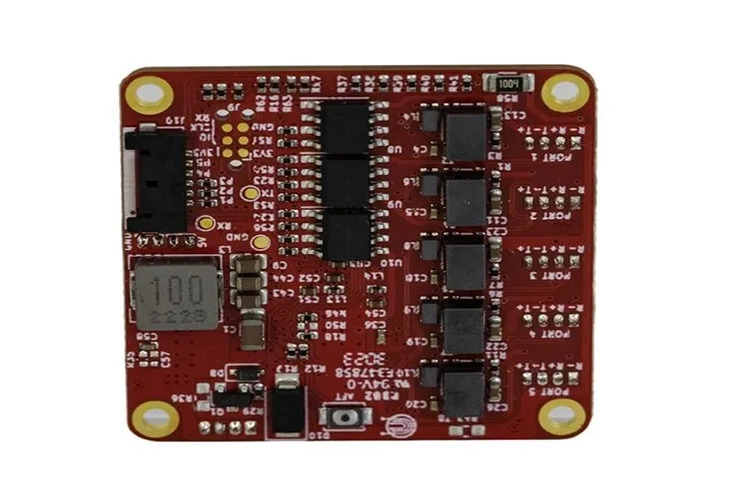

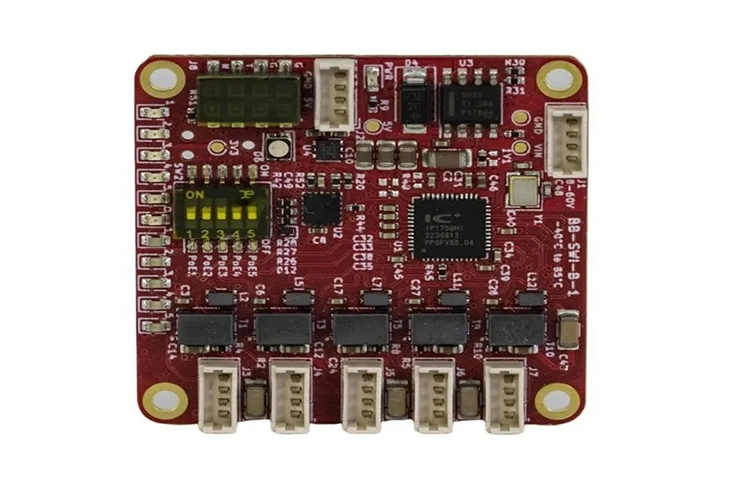

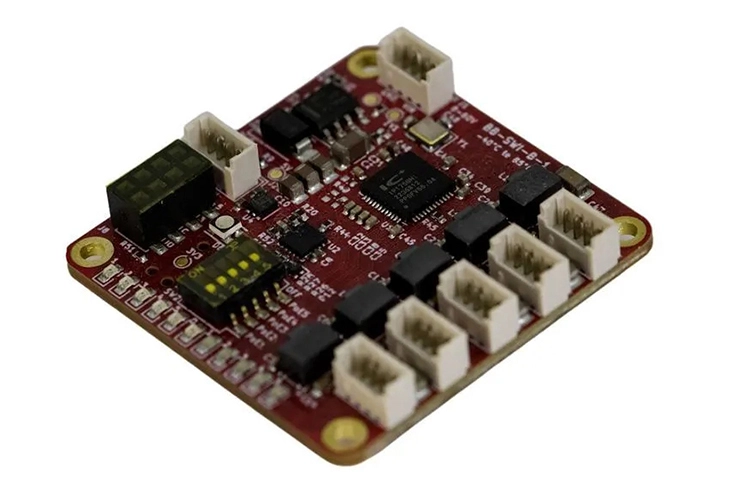

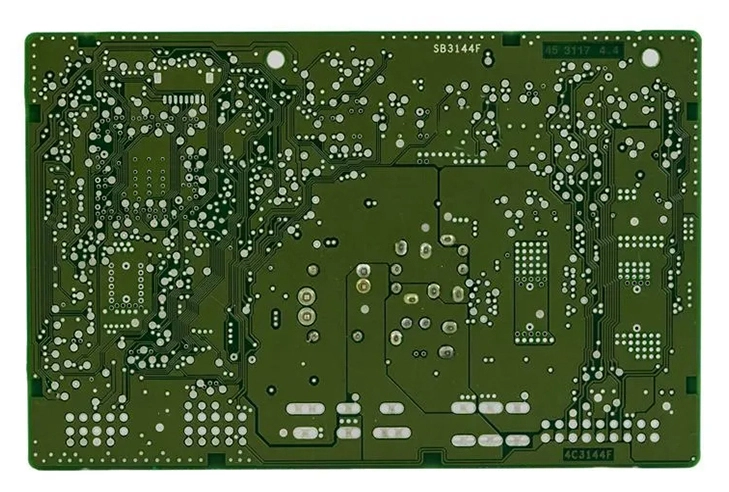

Ring PCB provides custom 1–3 oz FR-4 smart robotics PCB assembly with high reliability and stability. Turnkey solutions include PCB fabrication, component sourcing, SMT assembly, and functional testing. Ideal for industrial robots, service robots, medical robotics, aerospace, and consumer robots.

Key Features of Smart Robotics PCBA

-

High Precision Placement

Pick-and-place machines in PCBA achieve micron-level accuracy, ensuring reliable component placement and reducing the risk of malfunctions in robotic systems. -

Automation-Driven Efficiency

Automated assembly lines streamline repetitive tasks such as feeding, soldering, and testing, increasing production throughput and lowering labor costs. -

Intelligent Monitoring

Sensors, cameras, and data analytics enable real-time monitoring, early issue detection, and continuous process optimization for high-quality output. -

High Integration & Compact Design

Supports high-density layouts on compact PCBs, meeting the demand for smaller, more powerful robotic devices. -

Reliability & Stability

Advanced testing and quality management ensure long-term stability of electronic components across various environments. -

Customizable Solutions

Tailored PCBA for industrial, service, or specialized robots, supporting unique operational and functional requirements.

Core Components of Smart Robotics PCBA

-

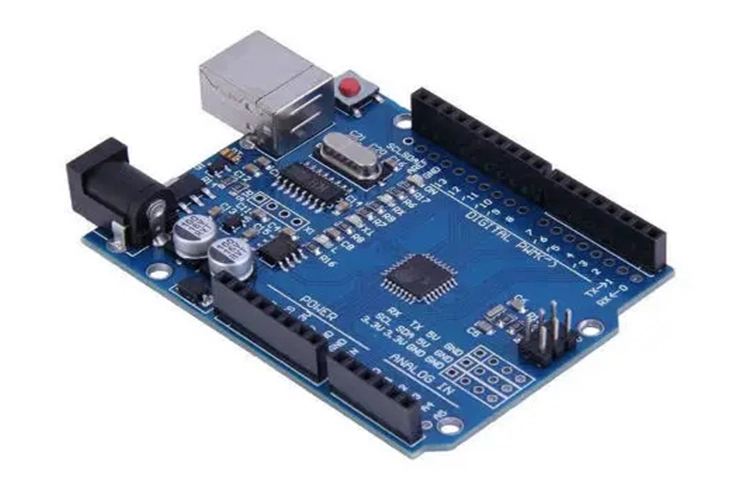

Microcontroller PCBA

-

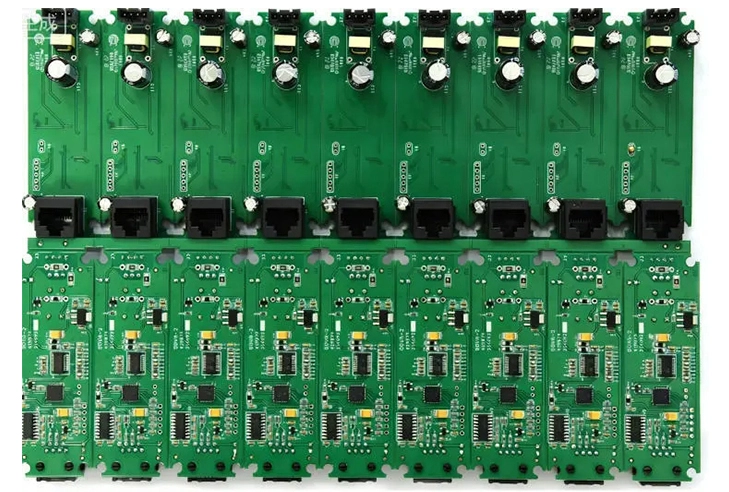

Motion Control PCBA

-

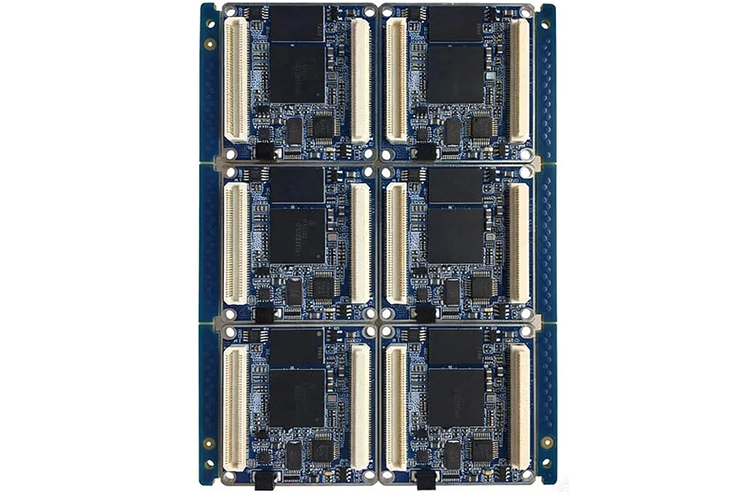

Sensor Interface PCBA

-

Vision Sensor PCBA

-

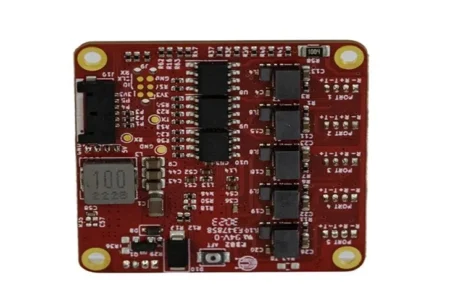

Wireless Communication PCBA

-

Wired Communication PCBA

-

Power Management PCBA

-

Power Conversion PCBA

Ring PCB customizes modules based on your drawings or specifications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Board Material | FR-4 (standard), Rogers (high-frequency), CEM-3 |

| Layer Count | 2–30+ layers (complexity-dependent) |

| Trace Width/Spacing | 0.1–0.5 mm (adjusted for current and impedance) |

| Via Size | 0.3–1.0 mm (smaller for high-density boards) |

| Copper Thickness | 1–3 oz (2–3 oz for high-power applications) |

| Surface Finish | HASL, ENIG, OSP (ENIG preferred for harsh environments) |

| Component Footprint | SMT (0402/0603 resistors, QFP/BGA ICs) |

| Impedance Control | 50–100 Ω (high-speed signals) |

| Power Distribution | Voltage regulation ±1%, ripple <50mV |

| Customizable Options | Thermal vias, EMI shielding, special packaging |

Additional specifications, including thermal management and connectors, can be customized to project requirements.

Applications of Smart Robotics PCBA

-

Industrial Robots – Production automation, material handling, soldering, and spraying systems with precise movement control and high-load operation.

-

Service Robots – Cleaning, delivery, and elderly-care robots with navigation, obstacle avoidance, and interaction capabilities.

-

Medical Robots – Surgical and diagnostic robots; high-precision PCBA ensures safe, accurate operation.

-

Aerospace & Defense – UAVs, robotic arms, and military-use robots requiring reliability, miniaturization, and extreme environment performance.

-

Consumer Robots – Educational and home-entertainment robots offering interactive and user-friendly experiences.

Why Choose Ring PCB?

-

Precision PCB Manufacturing

-

High-density 2–48 layer boards with blind/buried vias, 3/3mil trace/spacing, ±7% impedance control.

-

Self-owned factory with LDI laser exposure, vacuum lamination, and flying probe testers.

-

-

One-Stop Turnkey PCBA Services

-

Full assembly support: PCB fabrication, component sourcing, SMT assembly, functional testing.

-

DFM/DFA optimization reduces design risks and BOM costs.

-

Rigorous QC: X-ray inspection, AOI testing, and 100% functional validation.

-

-

Self-Owned Factory & Supply Chain Control

-

Vertical integration of raw materials, production, and testing.

-

Triple quality assurance: AOI + impedance testing + thermal cycling, defect rate <0.2%.

-

Certified ISO9001, IATF16949, RoHS compliance.

-

-

Advanced Soldering Capabilities

-

8-stage lead-free reflow and wave soldering ensures high-quality assembly and environmental compliance.

-

-

Global Experience & Reliability

-

17+ years supporting clients worldwide in industrial, medical, aerospace, and consumer robotics.

-

Custom solutions from prototyping to mass production.

-

Contact Us

📧 Email: rfq@ringpcb.com