In today’s fast-evolving electronics industry, reliable PCB and PCBA manufacturing is the foundation of product performance, quality, and time-to-market. From consumer electronics to industrial control, medical devices, and automotive systems, printed circuit boards play a critical role in every electronic product lifecycle.

Founded in 2008, Ring PCB is a professional PCB & PCBA manufacturer based in Shenzhen, China, specializing in high-quality PCB fabrication and full-turnkey PCB assembly services. With 18 years of industry experience, we provide stable, scalable, and cost-effective electronic manufacturing solutions to customers worldwide.

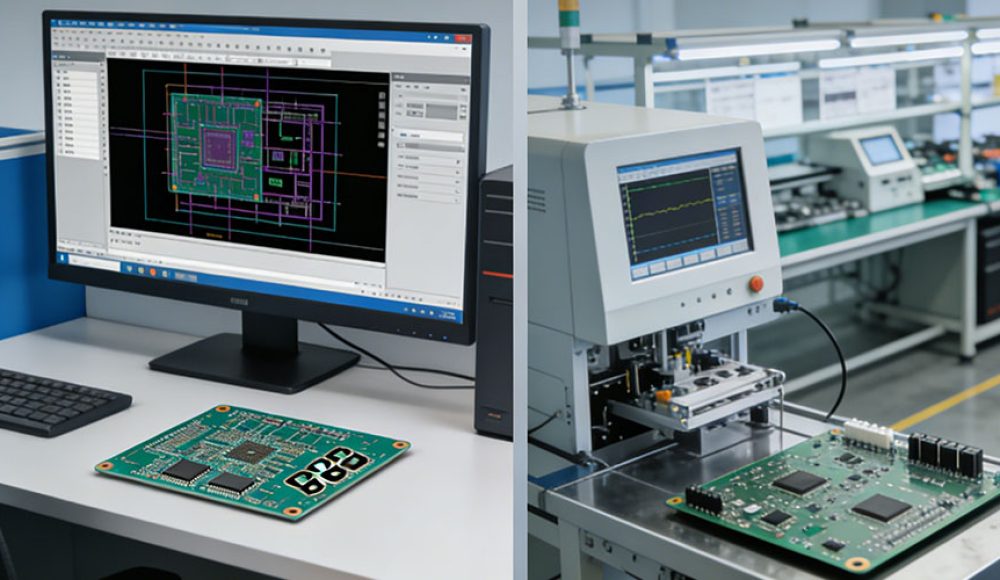

Comprehensive PCB Manufacturing Capabilities

PCB manufacturing is far more than producing circuit boards—it requires precision engineering, strict process control, and reliable materials. Ring PCB supports a wide range of PCB technologies to meet diverse application requirements.

Our PCB fabrication capabilities include:

-

Single-layer, double-layer, and multilayer PCBs

-

HDI PCBs and high-density designs

-

Rigid, flexible, and rigid-flex PCBs

-

High-frequency and high-speed PCBs

-

Metal core PCBs for thermal management

From 3-day rapid prototyping to high-volume production, our in-house manufacturing ensures consistent quality, controlled lead times, and flexible order support.

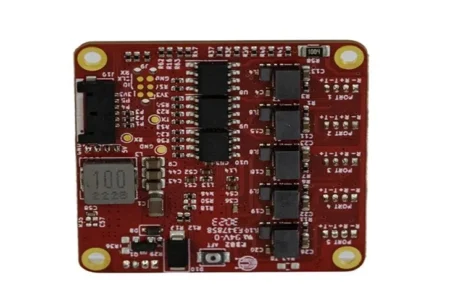

Full-Turnkey PCBA Manufacturing Services

To help customers reduce supply chain complexity, Ring PCB offers one-stop PCBA services, covering every step from PCB fabrication to final assembly and testing.

Our PCBA services include:

-

Electronic component sourcing

-

SMT and THT assembly

-

BGA, QFN, and fine-pitch component assembly

-

Functional testing and inspection

-

Final assembly and packaging

With advanced SMT lines and automated inspection systems, we ensure high assembly accuracy and production stability across both low-mix high-volume and high-mix low-volume projects.

Advanced Manufacturing Facility & Skilled Workforce

Ring PCB operates a 10,000-square-meter self-operated manufacturing facility in Shenzhen, supported by a professional team of 500 skilled employees. Our factory is equipped with advanced production and inspection equipment, including:

-

High-speed SMT placement machines

-

Automated optical inspection (AOI)

-

X-ray inspection systems

-

Flying probe and electrical testing equipment

This integrated manufacturing setup allows us to maintain strict quality control throughout the entire PCB and PCBA production process.

Certified Quality Management You Can Trust

Quality and reliability are non-negotiable in electronic manufacturing. Ring PCB operates under internationally recognized quality standards and certifications, including:

-

ISO9001

-

ISO14001

-

ISO13485 (Medical Devices)

-

IATF16949 (Automotive Electronics)

-

UL Certification

These certifications reflect our commitment to consistent quality, environmental responsibility, and compliance with global industry requirements.

Serving Global Industries and Applications

Ring PCB provides PCB and PCBA manufacturing services for a wide range of industries, including:

-

Consumer electronics

-

Industrial control systems

-

Medical equipment

-

Automotive electronics

-

Communication and networking devices

By combining engineering expertise with flexible manufacturing capacity, we help customers bring products to market faster while maintaining long-term reliability.

Your Trusted PCB & PCBA Manufacturing Partner

With 18 years of experience, advanced in-house manufacturing, and a customer-focused service model, Ring PCB is more than just a supplier—we are a long-term EMS partner.

Whether you need fast PCB prototyping, stable mass production, or complete turnkey PCBA solutions, Ring PCB delivers manufacturing support you can rely on.