In today’s electronics industry, product success depends not only on innovative design, but more importantly on manufacturing reliability. As electronic systems become faster, smaller, and more complex, PCB manufacturing has become the true foundation of stable and high-quality EMS solutions.

For companies seeking long-term performance, scalability, and consistent product quality, integrating advanced PCB manufacturing with professional EMS solutions is no longer optional—it is a strategic necessity.

Why PCB Manufacturing Determines Product Reliability

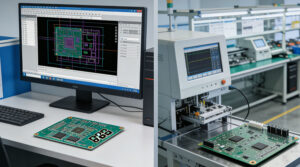

PCB manufacturing is a highly controlled, multi-stage process that directly impacts electrical performance, thermal stability, and mechanical strength. From material selection and layer lamination to precision drilling, imaging accuracy, surface finishing, and electrical testing, every step plays a critical role in final product quality.

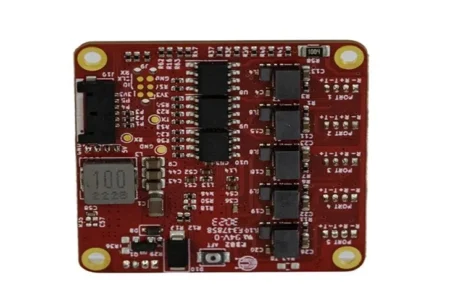

For advanced applications—especially HDI PCB assembly—manufacturing tolerances are extremely tight. Fine line widths, microvias, multilayer stack-ups, and impedance control require advanced equipment and strict process management. Without a strong PCB manufacturing foundation, even the most sophisticated circuit designs cannot achieve their expected performance or lifespan.

Founded in 2008, Ring PCB has accumulated 18 years of experience in PCB manufacturing and PCB assembly. With a self-owned modern factory covering approximately 10,000 square meters in Shenzhen and a professional team of over 500 employees, Ring PCB ensures stable quality, process consistency, and reliable delivery for customers worldwide.

The Role of EMS Solutions in Modern Electronics Manufacturing

Modern EMS solutions go far beyond PCB fabrication. They integrate PCB manufacturing, component sourcing, SMT assembly, functional testing, and logistics into one streamlined workflow. This integrated approach helps customers reduce supply chain risks, improve production efficiency, and maintain consistent quality across production stages.

For projects involving HDI PCB assembly, working with a single EMS solutions provider improves coordination between fabrication and assembly. This reduces communication errors, enhances traceability, and significantly shortens time-to-market.

Ring PCB offers flexible turnkey PCB assembly and full EMS solutions, supporting both small-batch prototyping and large-scale production. Rapid PCB prototyping can be completed within three days, while mass production can be achieved within seven days, helping customers accelerate product development and market entry.

Scalability and Customization Advantages

Professional PCB manufacturing combined with EMS solutions enables smooth scalability from prototype to volume production. Stable processes and strict quality control ensure consistent product performance regardless of order size.

Customization is equally essential. Different industries require specific materials, surface finishes, compliance standards, and testing procedures. Through customized PCB manufacturing and PCB assembly services, manufacturers can meet the diverse needs of industrial, medical, and communication applications.

Ring PCB products comply with international industry standards and are exported to more than 50 countries and regions. The company supports flexible order quantities and tailored solutions to meet various technical and regulatory requirements.

Choosing the Right PCB Manufacturing and EMS Partner

Selecting an experienced partner for PCB manufacturing and EMS solutions is critical for long-term success. Key factors include technical expertise, production capacity, quality management systems, and industry experience.

With nearly two decades of manufacturing experience, Ring PCB supports customers throughout the entire product lifecycle—from early-stage development and rapid prototyping to full turnkey mass production.

Conclusion

Reliable PCB manufacturing is the backbone of effective EMS solutions. When combined with professional HDI PCB assembly and integrated EMS capabilities, manufacturers can deliver scalable, high-performance, and cost-effective electronic products.

Ring PCB looks forward to building long-term partnerships with global customers and remains committed to providing efficient, reliable, and customized full-turnkey PCB manufacturing and EMS solutions.

Contact Information

📧 Email: rfq@ringpcb.com