| Place Of Origin: | Shenzhen, China | Certification: | ISO9001, ISO14001, ISO13485, And IATF16949 |

| PCB Type: | Rigid-flex PCB | Layer Count: | Up To 12 Layers |

| Thickness Range: | 0.3mm -3.2mm(customizable Based On Project Needs) | Max Board Size: | Up To 18" X 24" |

| Min Trace Width/Spacing: | 0.075mm(3 Mil) | Material Options: | Polyimide(flex Layers),FR4(rigid Layers),Adhesive- Less Materials |

| Min Hole Size: | 0.1mm (4 Mil) | Surface Finishes: | ENIG,OSP, Immersion Silver,immersion Tin,and Hard Gold |

| Stiffener Options: | Polyimide,FR4,Stainless Steel | Certifications: | IPC, RoHS, UL, ISO9001, ISO14001,ISO13485,IATF16949 |

| Testing And Inspection: | AOI,Electrical Testing,Thermal Cycling,Flexibility Testing | Application Areas: | Consumer Electronics,led Lights,Power SuppliesMedical Devices,LED Lighting,ect |

| Special Features: | Blind And Buried Vias,Controlled Impedance, Coverlay On Flex | Solder Mask Colors: | Yellow,White,Black,Green |

| Packaging Details: | Vacuum packing+Cardboard packing case | Supply Ability: | 50000㎡per week |

| Highlight: | custom rigid flex PCB manufacturing, one-stop PCB PCBA solution, factory direct PCB assembly | ||

Product Description

Ring PCB: Quick Turn Rigid & Flex PCB Manufacturer for Engineering Projects

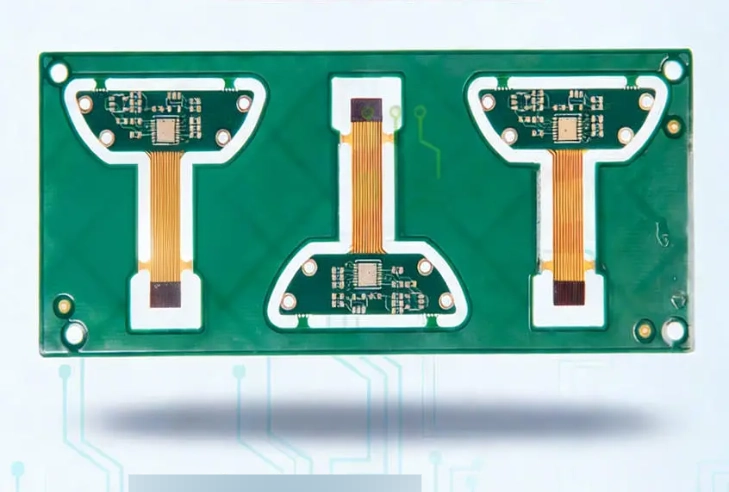

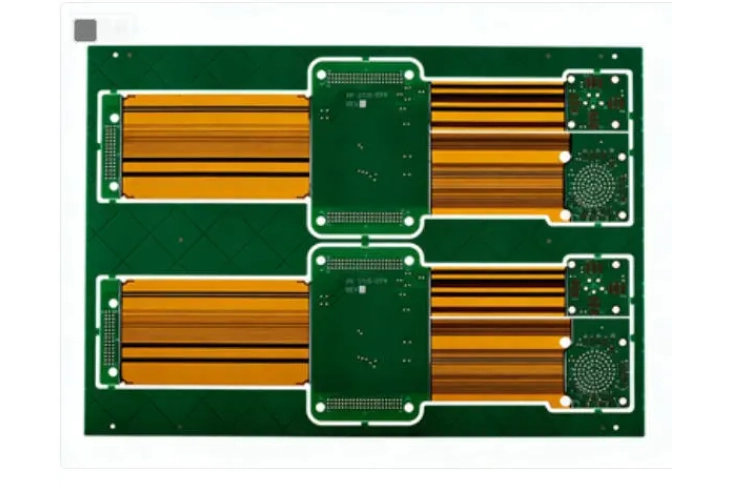

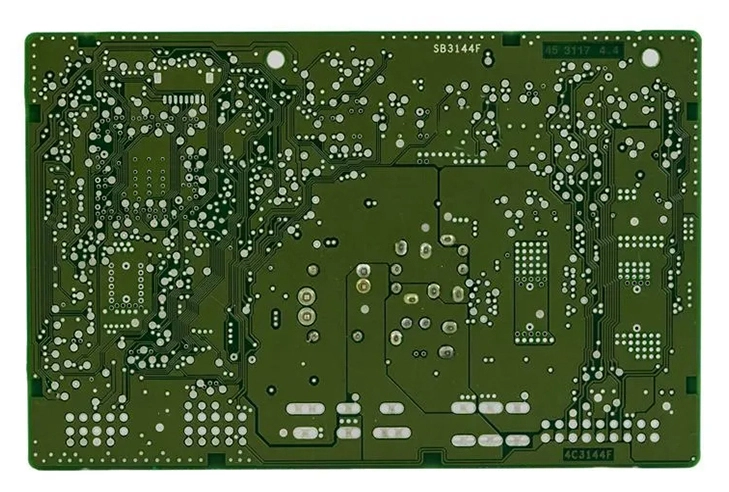

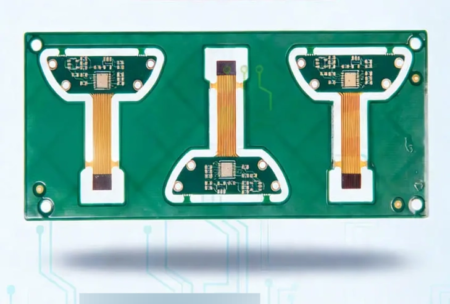

A Rigid & Flex PCB combines both rigid and flexible circuit layers into a single integrated structure. This hybrid design allows for mechanical stability in certain areas, while providing flexibility in others, making it ideal for compact, high-density, and space-constrained electronic products.

Rigid & Flex PCBs are commonly used in industries such as medical devices, industrial control, automotive electronics, aerospace, and advanced consumer electronics. By eliminating the need for connectors and cables, these boards improve signal integrity, reduce assembly complexity, and enhance product durability.

At Ring PCB, we offer customized Rigid & Flex PCB manufacturing and assembly services as part of our One-Stop PCB and PCBA solution. From prototype to mass production, we provide full-cycle support for your projects.

Product Features and Advantages

Key Features:

-

Integrated Rigid & Flex PCB Structure: Combines rigid PCB and flexible circuit sections in a single design.

-

High-Density Interconnection: Ideal for compact layouts, maximizing space efficiency.

-

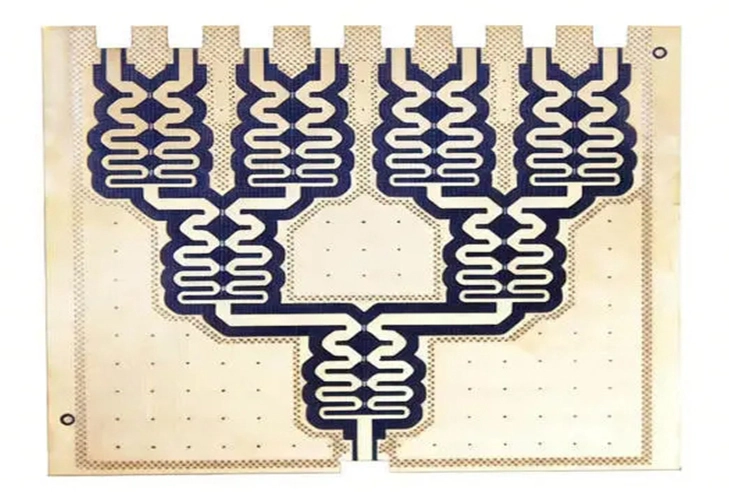

Flexible Bending Areas: Enables 3D assembly and adaptability to various product designs.

-

Surface Finish Options: Includes ENIG (Electroless Nickel Immersion Gold) and hard gold fingers for enhanced durability.

-

FPC with PI Stiffener: Improves mechanical strength and ensures better performance under dynamic conditions.

Main Advantages:

-

Reduced Connectors and Assembly Steps: Simplifies the design and production process.

-

Improved Signal Integrity and Reliability: Ensures consistent electrical performance.

-

Enhanced Durability: Designed to withstand dynamic environments and repeated flexing.

-

Optimized Space Utilization: Perfect for product miniaturization and complex, high-precision applications.

Technical Challenges in Rigid & Flex PCB Manufacturing

Manufacturing Rigid & Flex PCBs involves more technical complexity than standard printed circuit boards. Key challenges include:

-

Layer Alignment: Ensuring precise registration between rigid and flexible layers for consistent performance.

-

Material Combination: Managing different materials, such as FR-4 for rigid sections and polyimide for flexible sections, requires careful process control.

-

Impedance and Signal Integrity: Fine trace widths and spacing demand high-precision etching to maintain signal quality.

-

Mechanical Reliability: Bending areas must withstand repeated flexing without cracking or delamination.

At Ring PCB, our experienced engineering team and advanced manufacturing processes ensure that all challenges are overcome to deliver high-quality Rigid & Flex PCBs.

Typical Technical Parameters (For Reference Only)

| Parameter | Typical Specification |

|---|---|

| PCB Type | Rigid & Flex PCB |

| Layer Stack-up | 4 Layers (1R + 2F + 1R) |

| Board Thickness | 0.8 ± 0.1 mm |

| Min Trace Width / Spacing | 0.1 mm / 0.1 mm |

| Min PTH to Inner Layer Trace Spacing | 0.25 mm |

| Aspect Ratio | 4:1 |

| Surface Finish | ENIG |

| Special Technology | FPC with Hard Gold Fingers (PI Stiffener Added) |

| Application Areas | Medical, Industrial, Automotive, Aerospace |

Note: Actual specifications can be customized according to customer design requirements. Please contact our professional sales team for detailed consultation.

Applications of Rigid & Flex PCBs

Our Rigid & Flex PCBs are used across multiple high-performance industries:

-

Medical & Healthcare Devices: Ensuring compact, flexible designs for portable medical devices and implants.

-

Industrial Automation & Control Systems: Designed for high-reliability applications requiring precision and durability.

-

Automotive Electronics & Sensors: Withstanding harsh conditions in automotive environments such as vibration and extreme temperatures.

-

Aerospace & Defense: Meeting the space and reliability demands of aerospace components.

-

High-End Consumer Electronics: Enabling sleek, functional designs for mobile devices, wearables, and other advanced electronics.

One-Stop Service for PCB & PCBA Solutions

Ring PCB offers a complete One-Stop PCB and PCBA solution. From rigid-flex PCB fabrication to component sourcing, SMT assembly, and functional testing, we handle every step of the process. Whether you need prototyping or mass production, our expert team delivers high-quality results every time.

Core Advantages of Ring PCB

-

Advanced Engineering for Precision PCB Manufacturing

-

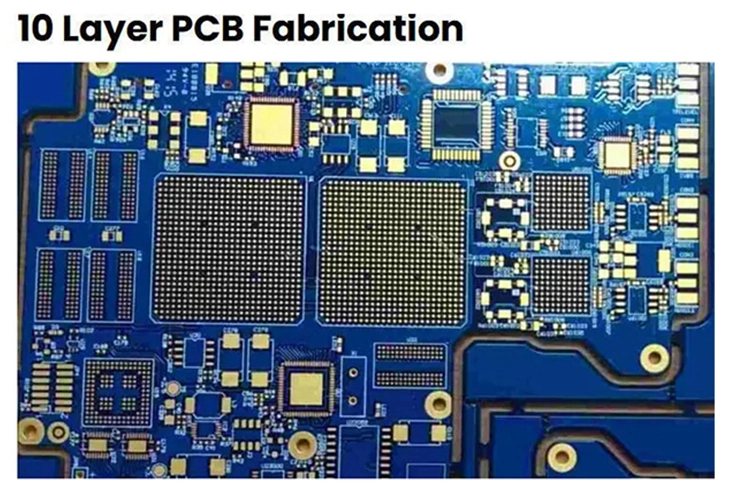

High-density stack-up (2-48 layers) with blind/buried vias and ±7% impedance control ideal for 5G, industrial control, medical, and automotive electronics.

-

Smart Manufacturing: State-of-the-art facilities with LDI laser exposure, vacuum lamination, and flying probe testers, adhering to IPC-6012 Class 3 standards.

-

-

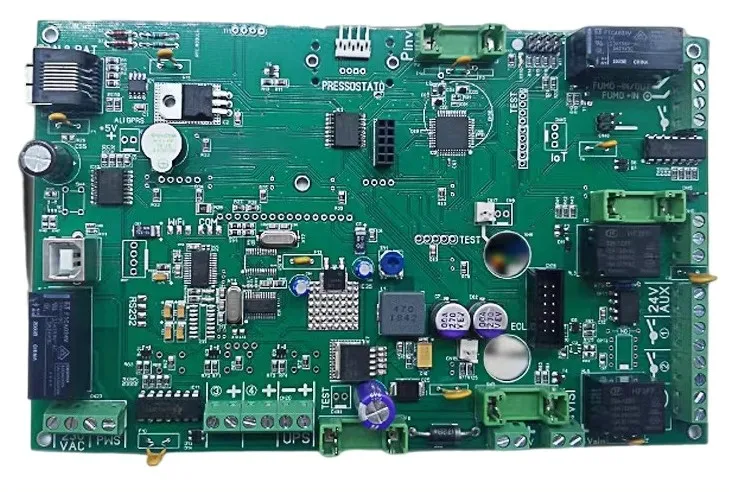

Integrated PCBA Services | One-Stop Turnkey Solutions

-

Full Assembly Support: From PCB fabrication to SMT assembly and functional testing.

-

DFM/DFA Optimization: Expert engineering team optimizes designs for reduced risks and BOM cost savings.

-

Rigorous Quality Control: X-ray inspection, AOI testing, and 100% functional validation ensure zero-defect delivery.

-

-

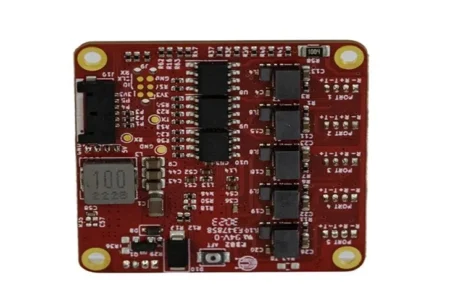

Self-Owned Factory with Full Supply Chain Control

-

Vertical Integration: Raw material procurement, production, and testing fully managed in-house.

-

Triple Quality Assurance: AOI, impedance testing, and thermal cycling, with a defect rate of <0.2% (industry average: <1%).

-

Global Certifications: ISO9001, IATF16949, and RoHS compliance.

-

Why Choose Ring PCB?

-

17 Years of Excellence in PCB and PCBA manufacturing, offering high-quality, reliable products for critical applications.

-

Self-Owned Factories in Shenzhen and Zhuhai ensure full control over production and meeting tight deadlines.

-

End-to-End Technical Support: From design to mass production, we support every phase of your project.

-

Fast Turnaround: Prototyping within 7 days and mass production within 15 days.

-

Global Reach: Serving over 50 countries with long-term industrial partnerships.

Contact Us

📧 Email: rfq@ringpcb.com