| Place Of Origin: | Shenzhen, China | Certification: | ISO9001, ISO14001, ISO13485, and IATF16949. |

| Type: | Hotel Communication Transmission Board PCB Assembly | Board Thickness: | Usually 0.8 - 2.4mm |

| Line Width/Spacing: | Commonly 0.1 - 0.3mm / 0.1 - 0.3mm | Surface Finish: | ENIG (Electroless Nickel Immersion Gold), HASL (Hot - Air Solder Leveling), Etc. |

| Operating Temperature: | -40°C - 85°C | Signal Frequency: | Ranges From Low - Frequency (kHz) To High - Frequency (GHz) Depending On Application |

| Power Consumption: | Varies Widely Based On Components, E.g., A Few MW To Several W | Certifications: | IPC, RoHS, UL, ISO9001, ISO14001,ISO13485,IATF16949 |

| Testing And Inspection: | Automated Optical Inspection (AOI), X-ray Inspection | Assembly Accuracy: | Tolerance Within ±0.05 - 0.1mm For Component Placement |

| Insulation Resistance: | ≥1000MΩ | Other Service: | We Can Help With The Procurement Of Electronic Components On Behalf Of Customers. |

| Application Areas: | Are Used In A Wide Array Of Devices, Including: Base Stations For Mobile Networks. Routers And Modems For Internet Connectivity. Satellite Communication Systems For Global Coverage. Optical Networking Equipment For High-speed Data Transfer. | Packaging Details: | Vacuum packing+Cardboard packing case |

| Supply Ability: | 50000㎡per week | ||

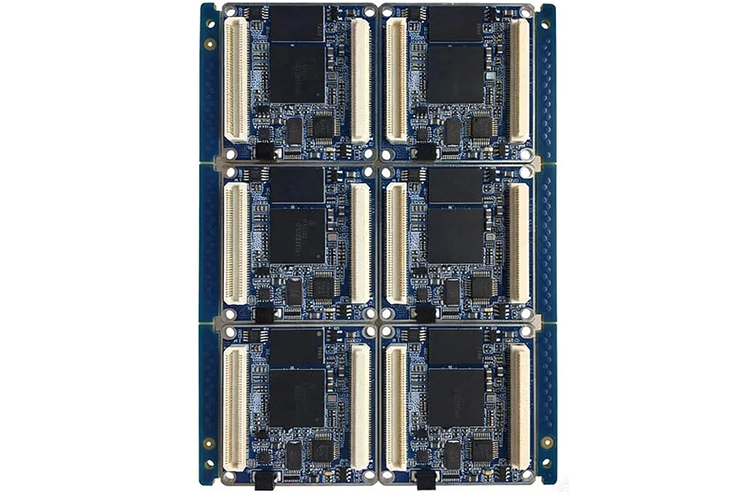

| Highlight: | 16 Layer FR-4 PCB Assembly, 6 Layer FR-4 PCB Assembly | ||

Product Description

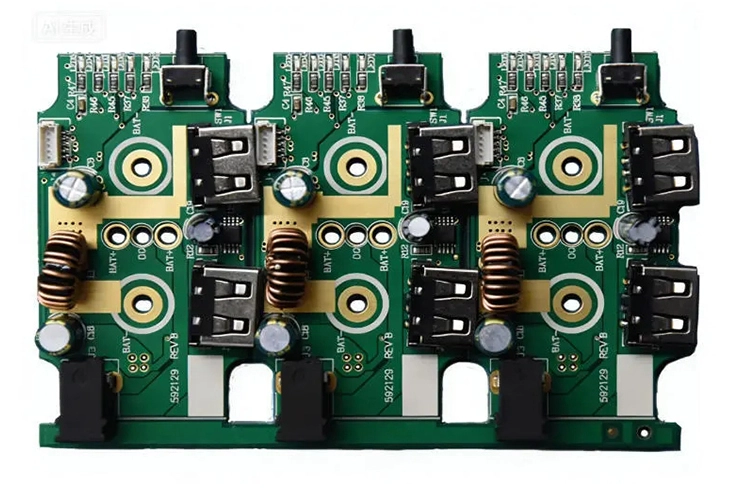

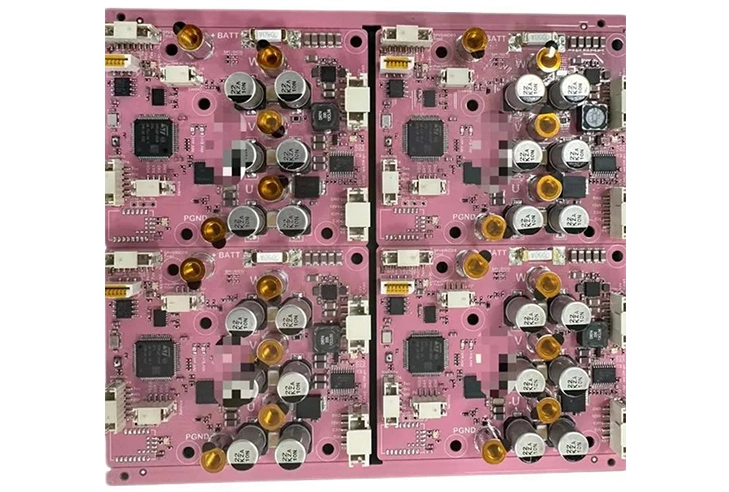

Custom Hotel Communication Transmission Board PCBA

Reliable High-Speed Data Transmission for Hotel Networks & IoT Systems

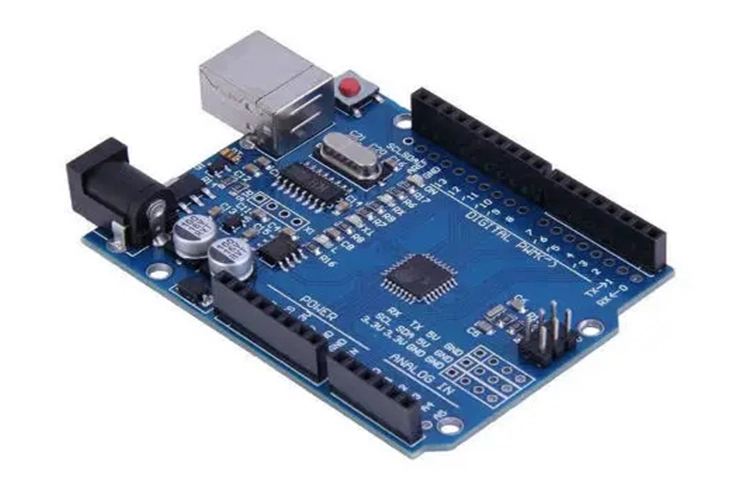

Ring PCB provides 6–16 layer FR-4 hotel communication transmission board PCB fabrication and full turnkey PCB assembly services, designed for stable, high-speed data transmission in modern hotel networks and smart building systems.

With 17 years of PCB & PCBA manufacturing experience, we support hotel communication infrastructure including IP networks, PBX systems, smart room controls, IoT gateways, and wireless communication modules, from fast prototyping to mass production.

Product Features & Advantages

1. High-Frequency Performance & Signal Integrity

Designed for hotel communication systems requiring stable, uninterrupted data transmission, our PCBs support Wi-Fi, 4G/5G, Ethernet, and IoT communication applications with minimal signal loss.

-

Material Options: High-Tg FR-4 (Tg ≥170°C), Rogers

-

Layer Count: 6–16 layers

-

Min. Hole Size: 0.2 mm

-

Trace Width / Spacing: 4–6 mil

-

Surface Finish: ENIG, Immersion Silver

-

Compliance: IPC-A-610 Class 2 / Class 3

✅ 100% Electrical Testing: ICT, FCT, and thermal shock testing (288°C / 10s) ensure long-term reliability.

2. Robust Thermal Management

Hotel communication equipment operates continuously. Our multilayer PCB structures and high-Tg materials provide excellent thermal stability, preventing deformation and performance degradation during long-term operation.

3. Multi-Protocol Compatibility

Designed for seamless integration with hotel systems:

-

RS485

-

Ethernet

-

Zigbee

-

Modbus

Long-Distance Stability:

RS485 differential signaling ensures reliable communication up to 1200 meters, even in electrically noisy environments.

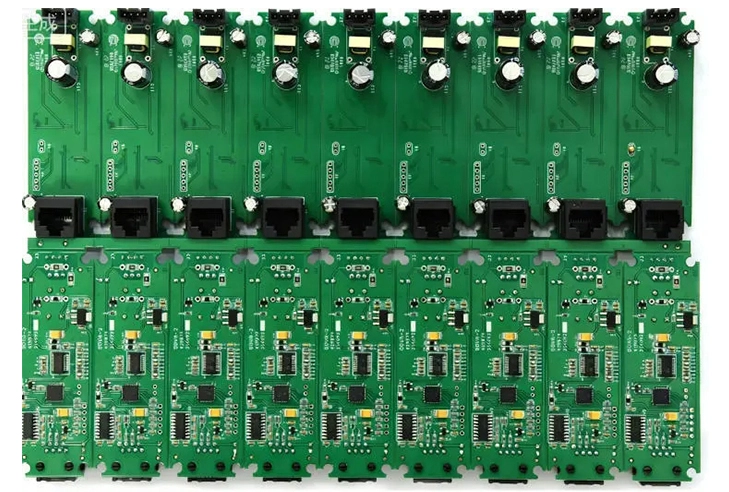

4. Customization & Turnkey Capability

-

Full Lifecycle Support: PCB fabrication + component sourcing + SMT/DIP assembly + testing

-

Material Flexibility: FR-4, Rogers, Teflon

-

Surface Finishes: HASL (Lead-Free), OSP, ENIG, Immersion Silver

-

Rapid Prototyping:

-

24-hour quick-turn for small batches (1+ pcs)

-

Scalable mass production for volume orders

-

5. Global Compliance & Quality Assurance

-

Certifications: ISO9001, IATF16949, RoHS

-

Market Compliance: CE / FCC (for wireless modules)

-

Manufacturing Standards: IPC-A-610 Class 2 / Class 3

Over the past 17 years, Ring PCB has served more than 20,000 customers worldwide, delivering customized PCB and PCBA solutions across communication, industrial control, and IoT sectors.

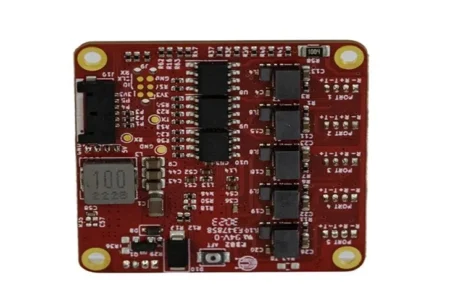

Typical Communication PCBA Applications

-

Hotel communication backbone systems

-

Routers & network switches

-

Smart hotel room controllers

-

Wireless access points

-

IoT communication gateways

Common Technical Parameters

| Parameter | Specification |

|---|---|

| PCB Layers | 6–16 Layers |

| Board Thickness | 0.8 – 2.4 mm |

| Line Width / Spacing | 0.1 – 0.3 mm |

| Surface Finish | ENIG, HASL, OSP |

| Operating Temperature | -40°C to +85°C |

| Signal Frequency | kHz – GHz |

| Assembly Accuracy | ±0.05 – 0.1 mm |

| Insulation Resistance | ≥1000 MΩ |

Why Choose Ring PCB?

17 Years of Manufacturing Excellence

Self-owned factory with full process control.

One-Stop Full Turnkey Service

PCB fabrication + component sourcing + SMT assembly + functional testing.

Advanced Production Equipment

LDI exposure, vacuum lamination, AOI, X-ray inspection, flying probe testing.

Reliable Soldering Technology

8-stage lead-free reflow soldering and wave soldering ensure assembly stability and RoHS compliance.

Important Notice

-

All products are customized services. Please contact us before placing an order.

-

Product images are real; minor color differences may occur due to lighting and display variations.

Contact Us

📧 Email: rfq@ringpcb.com