| Place Of Origin: | Shenzhen, China | Certification: | ISO9001, ISO14001, ISO13485, And IATF16949 |

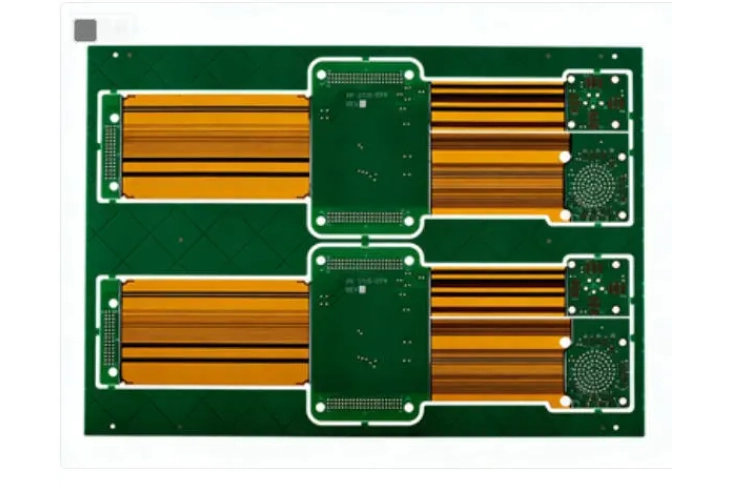

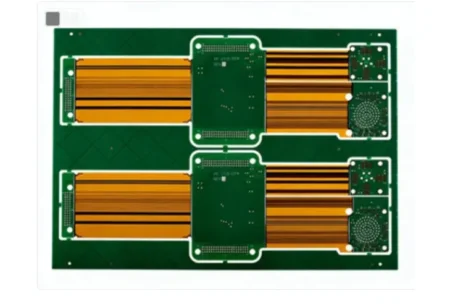

| PCB Type: | Rigid-flex PCB | Layer Count: | Up To 12 Layers |

| Thickness Range: | 0.3mm -3.2mm(customizable Based On Project Needs) | Max Board Size: | Up To 18" X 24" |

| Min Trace Width/Spacing: | 0.075mm(3 Mil) | Material Options: | Polyimide(flex Layers),FR4(rigid Layers),Adhesive- Less Materials |

| Min Hole Size: | 0.1mm (4 Mil) | Surface Finishes: | ENIG,OSP, Immersion Silver,immersion Tin,and Hard Gold |

| Stiffener Options: | Polyimide,FR4,Stainless Steel | Certifications: | IPC, RoHS, UL, ISO9001, ISO14001,ISO13485,IATF16949 |

| Testing And Inspection: | AOI,Electrical Testing,Thermal Cycling,Flexibility Testing | Application Areas: | Consumer Electronics,led Lights,Power SuppliesMedical Devices,LED Lighting,ect |

| Special Features: | Blind And Buried Vias,Controlled Impedance, Coverlay On Flex | Solder Mask Colors: | Yellow,White,Black,Green |

| Packaging Details: | Vacuum packing+Cardboard packing case | Supply Ability: | 50000㎡per week |

| Highlight: | Custom Rigid-Flex PCB solutions, Professional Rigid-Flex PCB supplier, OEM Rigid-Flex PCB solutions | ||

Product Description

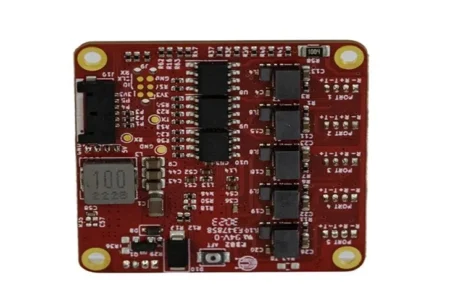

Ring PCB: Custom Rigid-Flex PCB Solutions for OEM & EMS

Ring PCB is a leading manufacturer specializing in rigid-flex PCBs for OEM (Original Equipment Manufacturer) and EMS (Electronics Manufacturing Services). With over 17 years of experience, we offer high-quality rigid-flex PCB assembly and turnkey PCB solutions tailored to the specific needs of industries including aerospace, automotive, medical, consumer electronics, and industrial applications.

What Are Rigid-Flex PCBs?

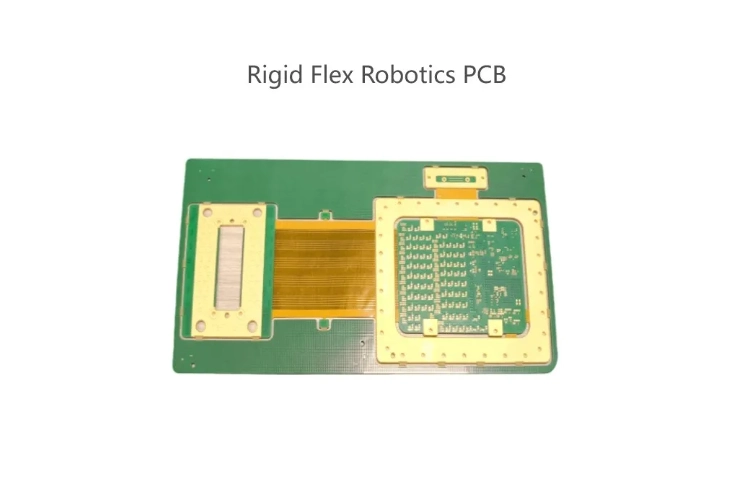

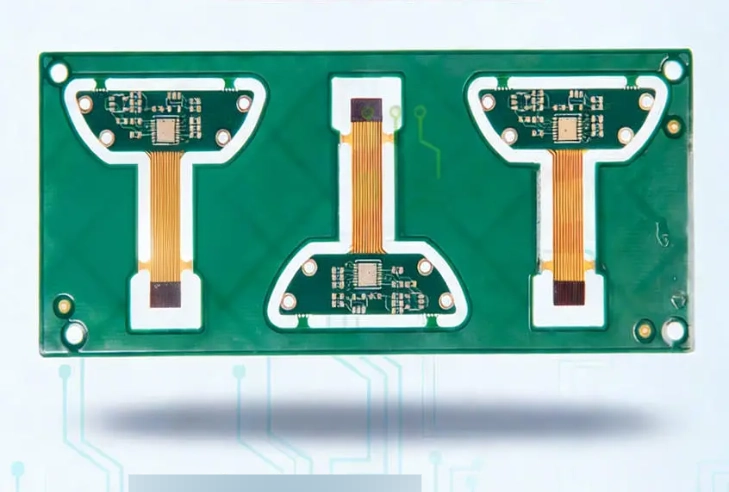

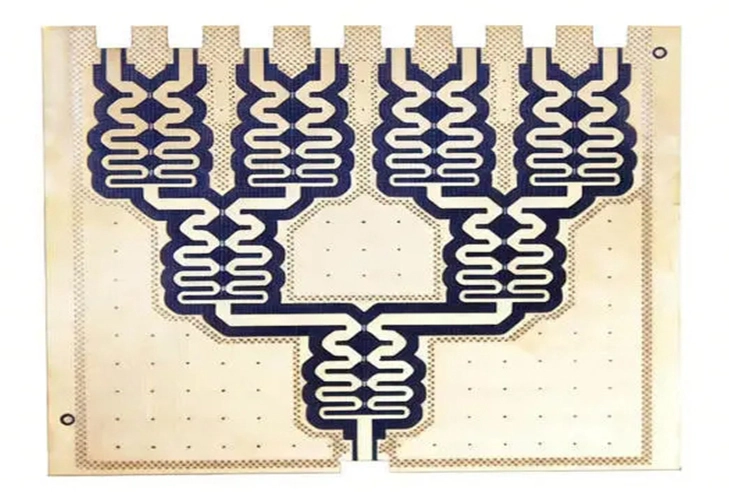

Rigid-flex PCBs combine both rigid and flexible layers within a single circuit board, providing support where needed while allowing flexibility in tight or complex spaces. These rigid-flex boards deliver the best of both worlds: sturdy, stable performance in rigid areas, and bendability and flexibility where necessary. They are lightweight, compact, and perfect for applications requiring both stability and flexibility.

Key Product Features of Rigid-Flex PCBs

-

Superior Flexibility & Space Efficiency

Our rigid-flex PCB boards are designed to bend, fold, or twist in confined spaces, maximizing space utilization while maintaining electrical stability for complex and compact devices. -

Durability & Reliability

Crafted from high-quality materials, our rigid-flex PCBs are built to withstand harsh environmental conditions including vibration, temperature fluctuations, and mechanical stress. These boards provide enhanced mechanical strength, minimizing solder joint failures and ensuring reliability for critical applications. -

Exceptional Electrical Performance

With advanced manufacturing techniques and precise circuit routing, our rigid-flex PCBs ensure superior signal integrity and low electrical interference. They are capable of supporting high-speed data transmission, making them ideal for modern electronic systems that require stable performance. -

Customizable Design Options

Understanding that each project has unique requirements, Ring PCB offers fully customizable rigid-flex PCB solutions, including adjustments to layer structure, material selection, and board form factors, ensuring a perfect fit for your product’s needs. Fast prototyping is available, with sample production completed in just 7 working days and mass production in 15 working days.

Advanced Manufacturing Processes for Rigid-Flex PCBs

At our state-of-the-art facilities in Shenzhen, Ring PCB uses advanced technologies to produce high-quality rigid-flex PCBs. Key processes include:

-

Lamination & Bonding: Using precise lamination techniques, we ensure a seamless bond between rigid and flexible layers, preventing warping and misalignment.

-

Laser Drilling & Routing: Our laser drilling technology allows for precise hole and via formation, perfect for compact designs with small vias.

-

Controlled Impedance: To meet the demands of high-frequency signal integrity, we implement precise impedance control techniques that ensure the best performance of rigid-flex PCBs in their final applications.

-

Surface Finishing: We offer various surface finishes such as ENIG (Electroless Nickel Immersion Gold), HASL (Hot Air Solder Leveling), and Immersion Silver to enhance the durability and reliability of the PCBs.

Applications of Rigid-Flex PCBs

Our rigid-flex PCBs are used across various industries, including:

-

Aerospace & Defense: Ideal for applications in aircraft and defense systems where space is limited, and reliability is critical.

-

Automotive Electronics: Perfect for automotive components like advanced driver-assistance systems (ADAS) and infotainment modules, designed to withstand vibration and temperature changes.

-

Consumer Electronics: Essential for portable devices such as smartphones, wearables, and other compact electronic gadgets, offering space-saving designs without compromising functionality.

-

Medical Devices: Enabling reliable performance in medical equipment, including portable monitors, diagnostic tools, and implants, offering flexibility for unique device shapes.

Ring PCB’s Key Advantages

-

Advanced Engineering for Precision PCB Manufacturing

-

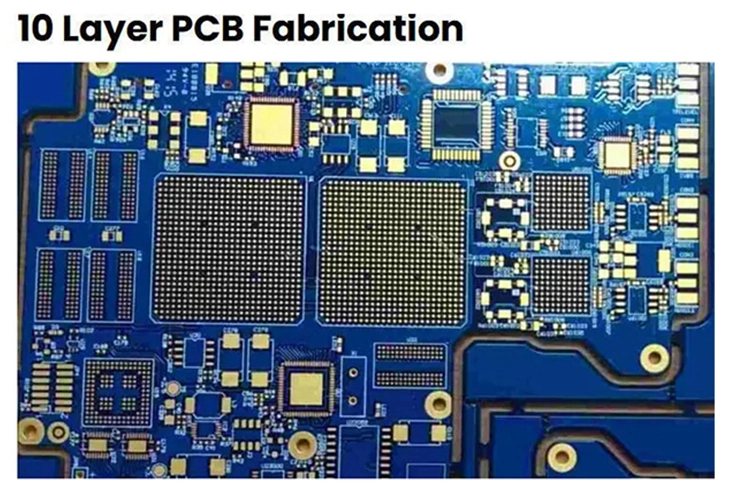

High-Density Stack-Up: 2-48 layer boards, ideal for 5G, industrial control, medical devices, and automotive electronics.

-

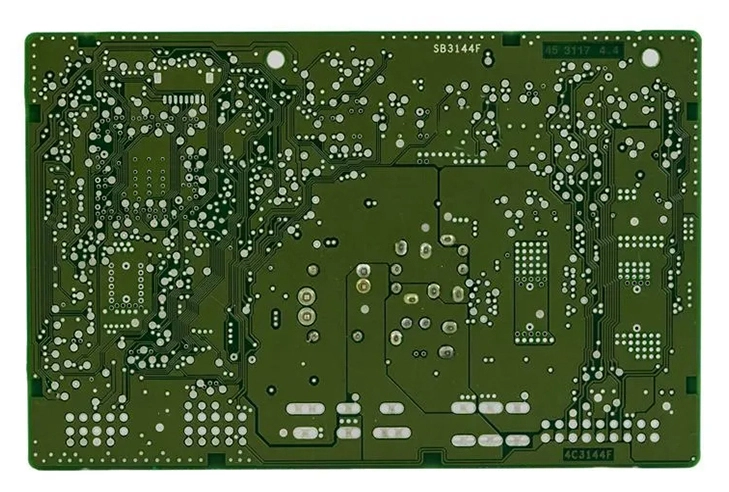

Smart Manufacturing: Self-owned facilities with LDI laser exposure, vacuum lamination, and flying probe testers, ensuring compliance with IPC-6012 Class 3 standards.

-

-

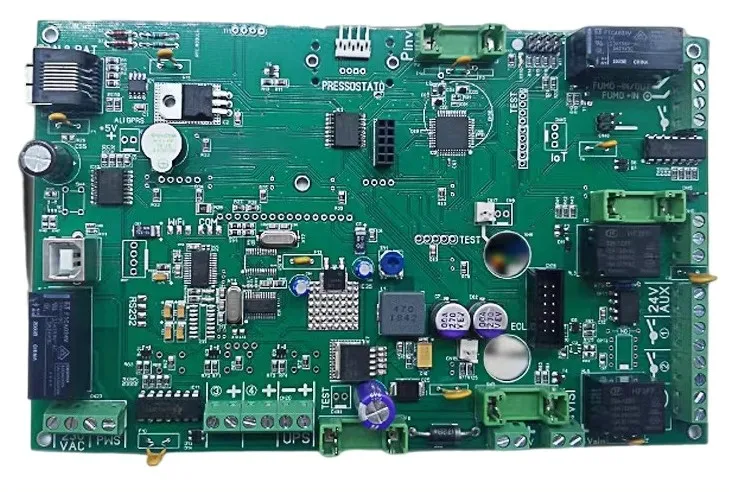

Integrated PCBA Services | One-Stop Turnkey Solutions

-

Full Assembly Support: PCB fabrication, component sourcing, SMT assembly, and functional testing, all under one roof.

-

DFM/DFA Optimization: Our expert engineering team optimizes designs to reduce risks and BOM costs, enhancing efficiency.

-

Rigorous Quality Control: X-ray inspection, AOI testing, and 100% functional validation ensure zero-defect delivery.

-

-

Self-Owned Factory with Full Supply Chain Control

-

Vertical Integration: We manage raw material procurement, production, and testing in-house, ensuring maximum control over the production process.

-

Triple Quality Assurance: AOI, impedance testing, and thermal cycling with a defect rate of <0.2% (industry average: <1%).

-

Global Certifications: ISO9001, IATF16949, and RoHS compliance to meet international standards.

-

Why Choose Ring PCB?

-

17 Years of Excellence in PCB and PCBA manufacturing, offering high-quality, reliable products for critical applications.

-

Self-Owned Factories ensure full control over the production process, allowing us to meet strict deadlines and guarantee consistent quality.

-

End-to-End Technical Support: From design and prototyping to mass production and final assembly, we provide comprehensive support at every stage.

-

Fast Turnaround: Prototype production within 7 days and mass production within 15 days to keep your projects on schedule.

-

Global Reach: Serving customers in over 50 countries with ongoing industrial partnerships.

Contact Us

📧 Email: rfq@ringpcb.com