| Place Of Origin: | Shenzhen, China | Certification: | ISO9001, ISO14001, ISO13485, And IATF16949 |

| PCB Assembly Type: | Automatic Control Data Operation Core PCB Assembly | PCB Material: | FR-4, CEM-3, Metal Core (Aluminum/Copper), High-Tg FR-4 (Tg ≥150°C) |

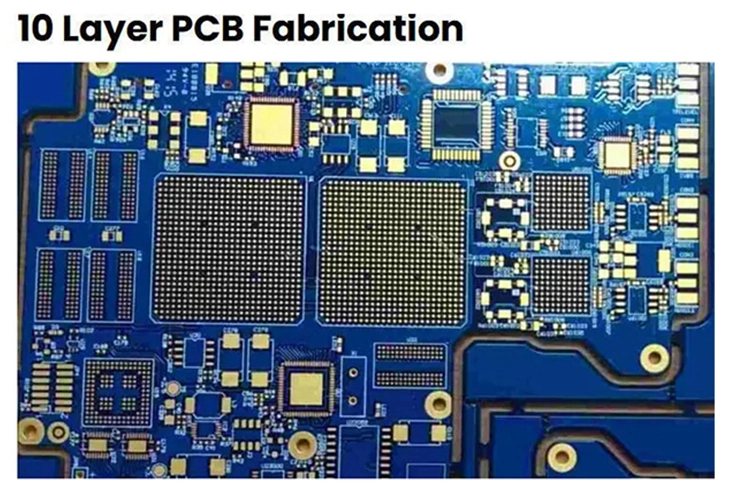

| Number Of Layers: | 2-Layer, 4-Layer, 6-Layer (up To 12-Layer For Complex Designs) | Board Thickness: | 0.8mm - 2.0mm (common), Up To 3.2mm For High-strength Needs |

| Surface Finishes: | HASL (Lead-Free), ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservative), Immersion Silver | Certifications: | IPC, RoHS, UL, ISO9001, ISO14001,ISO13485,IATF16949 |

| PCB Material: | FR - 4, Metal - Based PCBs, Etc. | Surface Finishes: | ENIG, HASL, OSP, Immersion Tin, Immersion Silver |

| Testing And Inspection: | Automated Optical Inspection (AOI), X-ray Inspection | Other Service: | We Can Help With The Procurement Of Electronic Components On Behalf Of Customers. |

| Packaging Details: | Vacuum packing+Cardboard packing case | Supply Ability: | 50000㎡per week |

| Highlight: | Customized FR-4 PCB Assembly, Quick Turn Circuit Boards Manufacturing, Industrial Device PCB Assembly | ||

Product Description

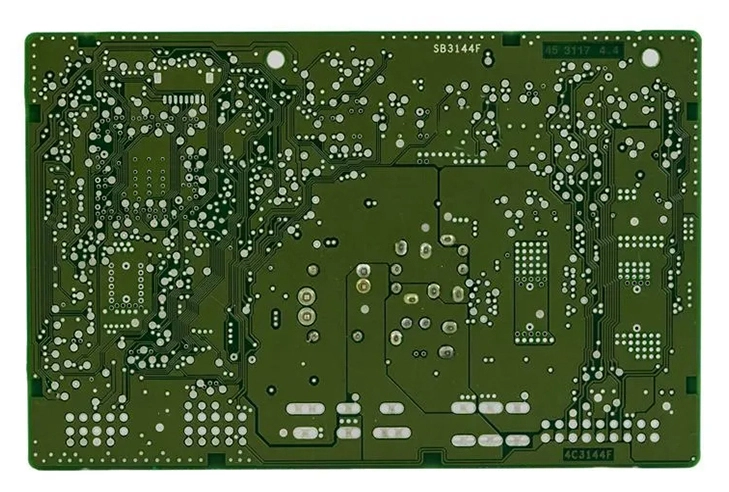

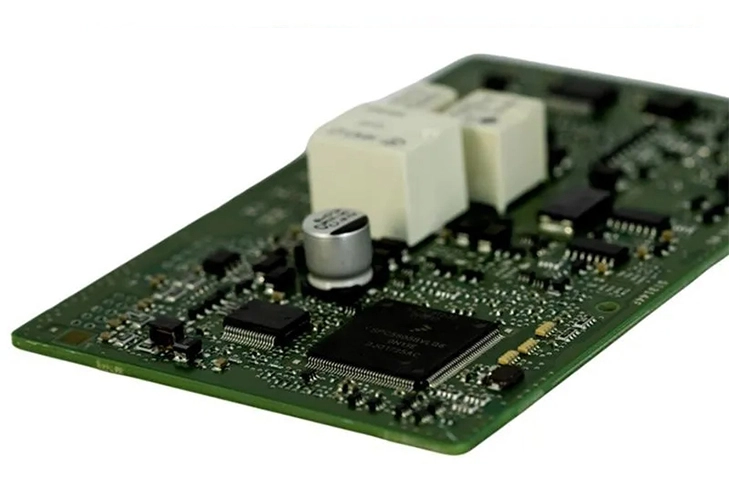

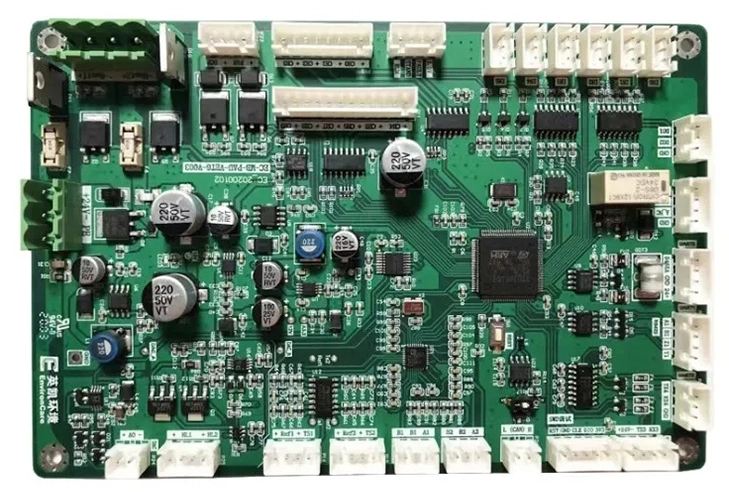

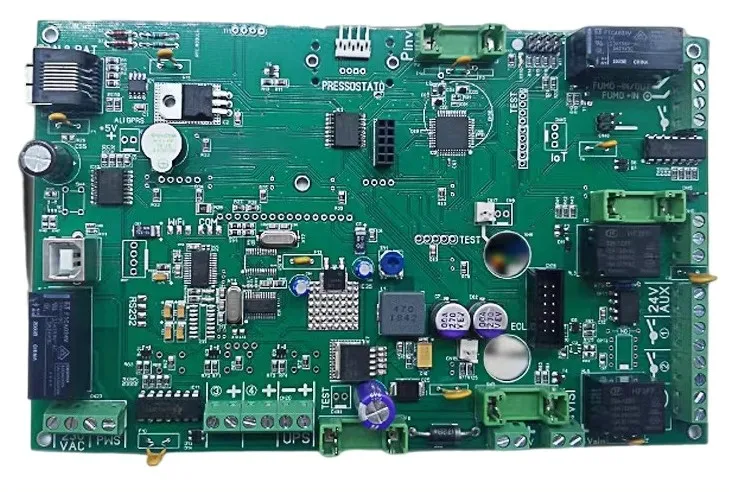

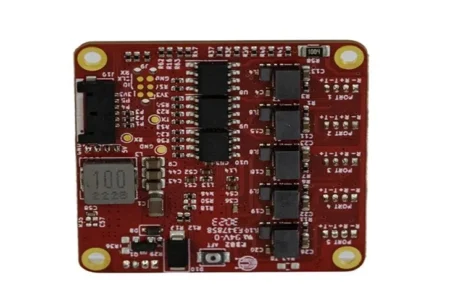

Customized FR-4 Industrial Device PCB Manufacturing & Assembly Services

Ring PCB is a professional manufacturer specializing in customized FR-4 multilayer industrial device PCB manufacturing and PCB assembly services. We provide quick turn circuit board fabrication, SMT & through-hole assembly, and one-stop turnkey PCBA solutions for industrial control and automation applications.

With 17 years of experience in PCB manufacturing and assembly, Ring PCB focuses on delivering high-reliability industrial-grade PCBs designed for harsh working environments. We are a manufacturing and assembly factory, not a design company. Customers provide Gerber files, BOM lists, and assembly drawings, and our engineering and production teams handle fabrication, assembly, testing, and delivery.

All production processes are carried out under strict quality control systems and comply with ISO9001, IATF16949, RoHS, and other international standards.

Product Features & Advantages

Industrial-Grade Reliability

Our FR-4 industrial PCBs are designed to operate reliably in demanding environments with resistance to dust, moisture, vibration, and temperature fluctuations. Standard operating temperature ranges from -40°C to +85°C, with extended options available.

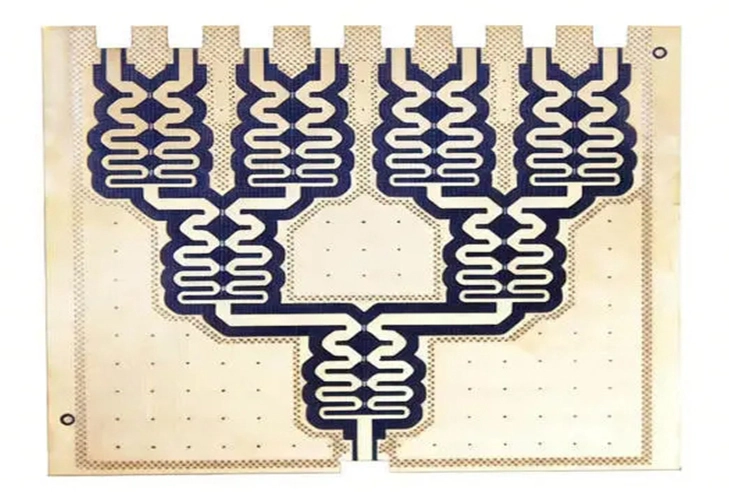

Stable Signal Processing & Anti-Interference

Advanced PCB layout and grounding design ensure excellent EMI/EMC performance. Integrated support for wireless modules such as RF, Bluetooth, ZigBee, LoRa, and other communication solutions enables stable long-distance signal transmission with minimal interference.

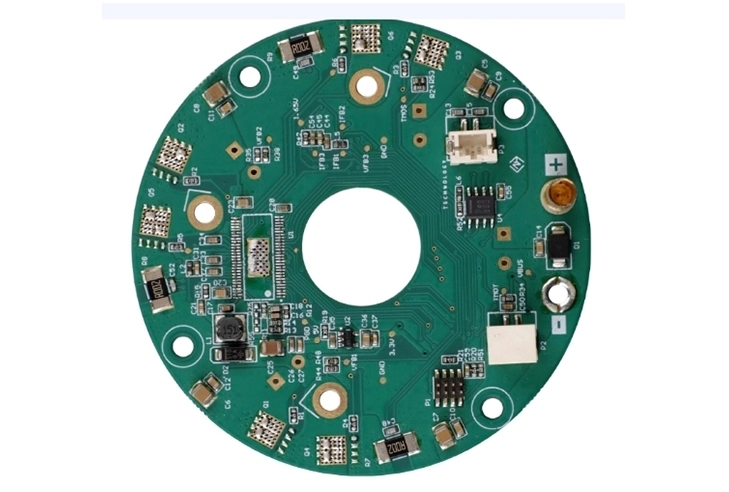

Compact & Rigid PCB Structure

Rigid PCB construction provides strong mechanical stability, preventing deformation in industrial equipment. High-density multilayer designs allow miniaturization without compromising durability or performance.

Long Service Life & Low Maintenance

Lead-free soldering processes and advanced SMT assembly technology improve solder joint reliability, reduce failure rates, and lower long-term maintenance costs.

✅ Technical Challenges We Address

-

Electromagnetic Interference (EMI) Control

Ground planes, shielding structures, ferrite beads, and optimized routing minimize signal distortion in noisy industrial environments. -

Thermal Management

Thermal vias, metal-core PCB options, and heat dissipation structures prevent overheating of high-power components. -

Miniaturization with High Integration

Multilayer PCB stack-ups, blind/buried vias, and compact layouts balance size constraints with functional complexity. -

Certification & Compliance

Support for CE, UL, RoHS, REACH, and industrial functional safety requirements through comprehensive testing.

Common Technical Parameters of Industrial Device PCB Assembly

| Parameter Category | Typical Specifications | Industrial Application Focus |

|---|---|---|

| Substrate Material | FR-4, High-Tg FR-4 (Tg ≥150°C), CEM-3, Metal Core (Aluminum / Copper) | Thermal stability, insulation, vibration resistance |

| Number of Layers | 2 Layer, 4 Layer, 6 Layer, up to 10+ Layers | Signal integrity, functional integration |

| Board Dimensions | 50 × 30 mm to 200 × 150 mm (Custom Available) | Space optimization for industrial devices |

| Board Thickness | 0.8 mm – 2.0 mm (Standard), up to 3.2 mm | Mechanical strength and durability |

| Copper Thickness | 1 oz (35μm), 2 oz (70μm), up to 3 oz | High current carrying capability |

| Surface Finish | Lead-Free HASL, ENIG, OSP, Immersion Silver | Corrosion resistance, solderability |

| Minimum Line Width / Spacing | 5mil / 5mil (Standard), 3mil / 3mil (HDI) | High-density routing |

| Hole Diameter | 0.3 mm – 3.0 mm (Blind/Buried via ≥0.15 mm) | Multilayer interconnection |

| Impedance Control | ±7% tolerance (optional ±5%) | High-speed & stable signal transmission |

| Operating Temperature | -40°C to +85°C (Standard), up to +125°C | Industrial environment adaptability |

| EMC / EMI Design | Ground planes, shielding, ferrite beads | Anti-interference performance |

| Assembly Technology | SMT, THT, Mixed Assembly | Flexible component mounting |

| Testing Methods | AOI, X-Ray, Flying Probe, FAI, Functional Test | 100% quality inspection |

| Certifications | ISO9001, IATF16949, RoHS, REACH, UL | Global compliance & reliability |

✅ PCBA Testing & Quality Control Capabilities

| Testing Type | Description |

|---|---|

| AOI Inspection | Automatic Optical Inspection for solder joints and component placement |

| X-Ray Inspection | BGA / QFN hidden solder joint inspection |

| Flying Probe Test | Electrical testing without fixtures |

| Functional Testing | Verifies actual working performance |

| First Article Inspection (FAI) | Ensures production consistency |

| QR Code Traceability | Full production tracking for each PCBA |

✅ Customization Services for Industrial PCB Assembly

| Customization Item | Available Options | Customer Value |

|---|---|---|

| Material Selection | FR-4, High-Tg, Rogers, PTFE, Metal Core | Match extreme environments |

| Layer Stack-Up | Optimized multilayer design | Improved signal integrity |

| Thermal Management | Thermal vias, heat sinks, metal core | Heat dissipation |

| Surface Treatment | ENIG, ENEPIG, Gold Finger | Long-term reliability |

| Protection Coating | Conformal coating (UV, Silicone, Parylene) | Moisture & dust resistance |

| Shape & Size | Cutouts, slots, irregular outlines | Perfect mechanical fit |

| Functional Integration | Wireless modules, protection circuits | Reduced development time |

| Packaging | Anti-static, vacuum packaging | Safe global shipping |

✅ Typical Industrial Applications

| Industry | Application Scenarios |

|---|---|

| Industrial Automation | PLCs, motion controllers, control panels |

| Power & Energy | Monitoring systems, inverters, power control |

| Transportation | Elevator control, railway systems |

| Environmental Equipment | Monitoring & treatment control systems |

| Smart Manufacturing | Industrial IoT devices, data acquisition |

Why Choose Ring PCB?

-

17 Years of Industrial PCB & PCBA Manufacturing Experience

-

Self-Owned Factory with full process control

-

Quick Turn Prototyping & Stable Mass Production

-

Advanced SMT lines, AOI, X-Ray, Flying Probe & Functional Testing

-

One-stop PCB Manufacturing + PCB Assembly + Turnkey PCBA Services

-

Dedicated engineering support for DFM / DFA optimization

Contact Us

📧 Email: rfq@ringpcb.com