| Place Of Origin: | Shenzhen, China | Certification: | ISO9001, ISO14001, ISO13485, and IATF16949. |

| Surface Finish: | ENIG (Electroless Nickel Immersion Gold), HASL (Hot - Air Solder Leveling), Etc. | Operating Temperature: | -40°C - 85°C |

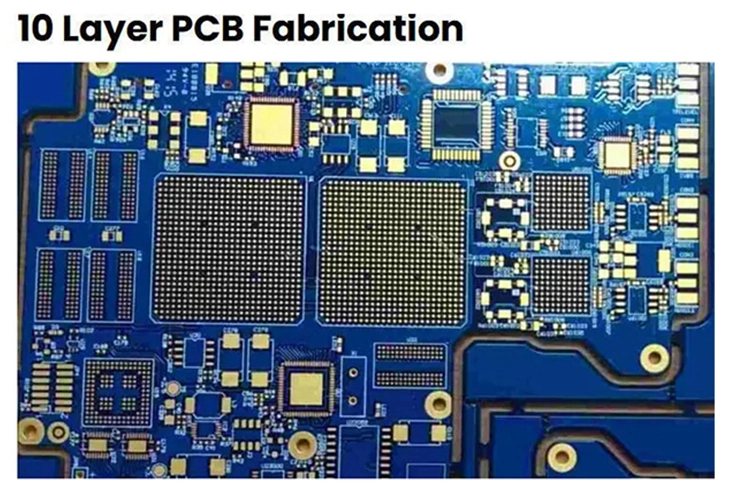

| Number Of Layers: | From 2 - Up To 48 Layers | Certifications: | IPC, RoHS, UL, ISO9001, ISO14001,ISO13485,IATF16949 |

| Testing And Inspection: | Automated Optical Inspection (AOI), X-ray Inspection | Assembly Accuracy: | Tolerance Within ±0.05 - 0.1mm For Component Placement |

| Other Service: | We Can Help With The Procurement Of Electronic Components On Behalf Of Customers. | Cost Efficiency: | Competitive Pricing And Cost Reduction Strategies |

| Environmental Responsibility: | Sustainable Practices And Green Initiatives | Customization: | Tailored Solutions To Meet Customer's Specific Requirements |

| Manufacturing Capabilities: | PCB Assembly, Box Build Assembly, Cable And Wire Harness Assembly, Testing And Inspection | Quick Turnaround Time: | Rapid Prototyping And Fast Production Lead Times |

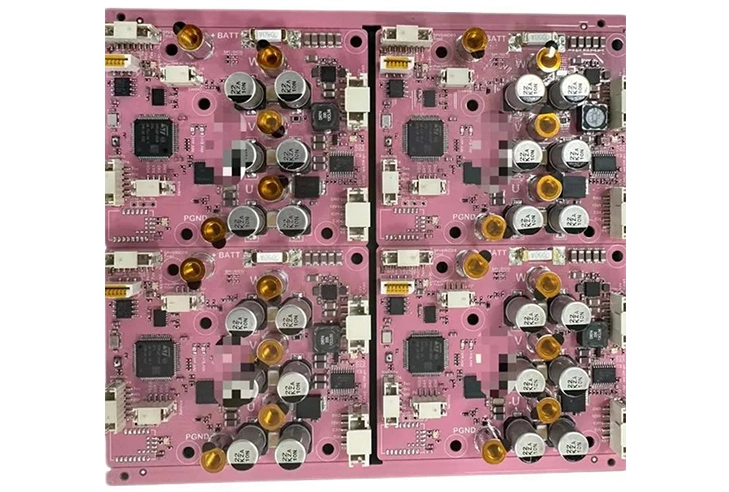

| Flexibility: | Ability To Handle Small To Large Production Volumes | Packaging Details: | Vacuum packing+Cardboard packing case |

| Supply Ability: | 50000㎡per week | ||

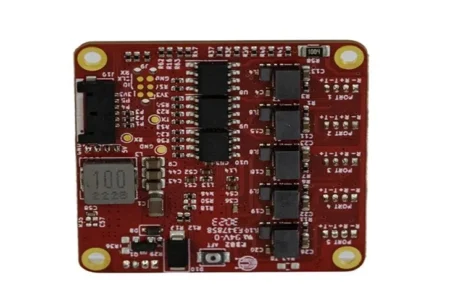

| Highlight: | Fast turnaround PCB manufacturer, Medical device PCBA assembly, 3-day rapid prototyping PCB | ||

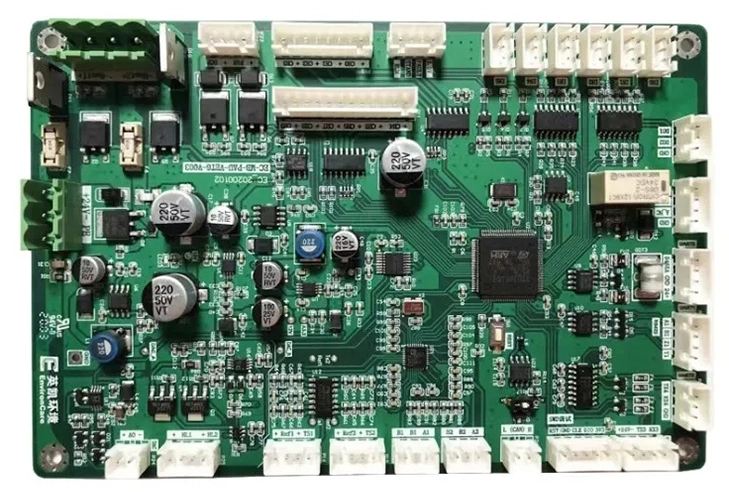

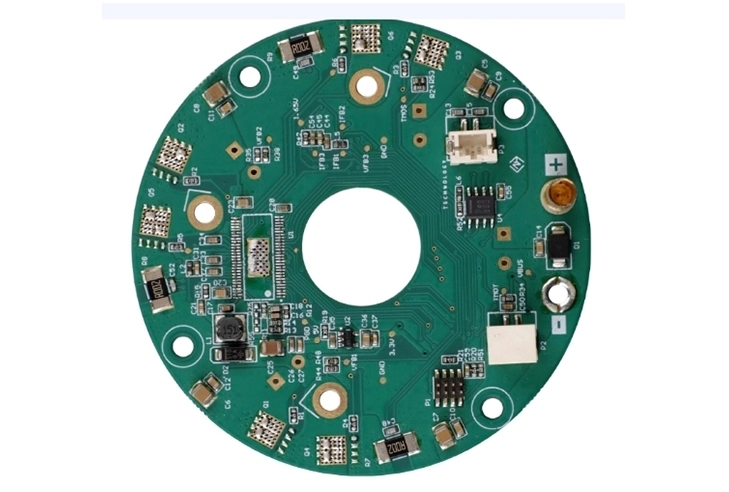

One-Stop PCB Assembly & Rapid Prototyping Services for Medical Devices

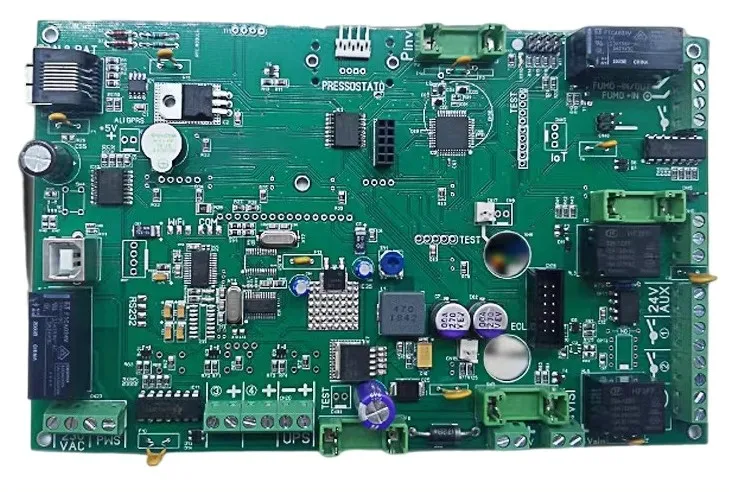

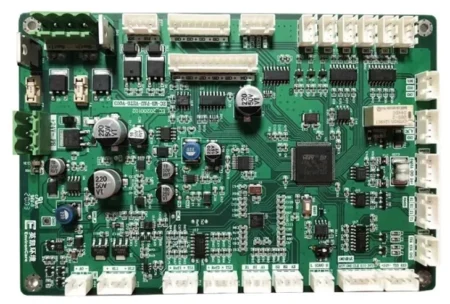

At Ring PCB, we specialize in multilayer PCB manufacturing and SMT assembly services for medical device applications, as well as industries such as automotive, telecommunications, industrial control, and consumer electronics.

With 17 years of industry experience, we have become a trusted PCB manufacturer and EMS provider, delivering high-quality, cost-effective, and fast-turnaround PCB & PCBA solutions.

Our two self-owned factories located in Shenzhen and Zhuhai, China, cover more than 5,000 square meters and are equipped with advanced SMT production lines, automated inspection systems, and professional testing facilities.

Supported by 500 skilled employees, Ring PCB efficiently handles rapid prototyping, small-batch orders, and high-volume production with consistent quality and reliable delivery.

Technical Challenges and Solutions

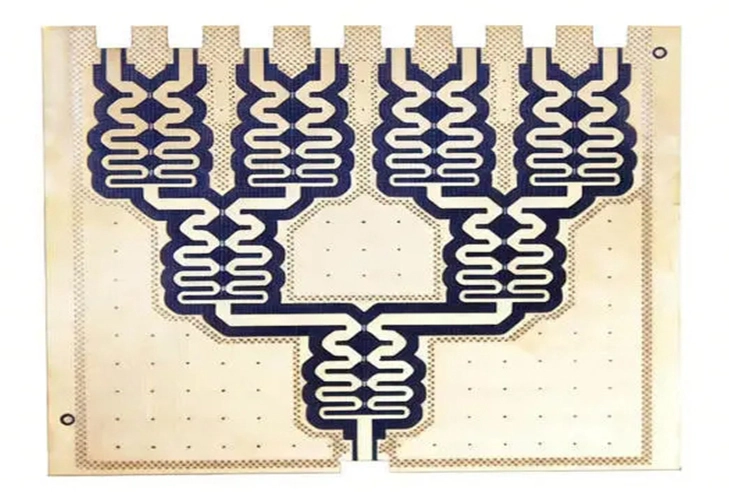

Manufacturing multilayer PCBs with up to 48 layers requires precise control of lamination pressure, dielectric thickness, and signal impedance.

Ring PCB’s experienced engineering team ensures:

-

Accurate layer registration and stable lamination quality

-

Controlled impedance for high-speed and RF applications

-

Optimized thermal management for power and industrial systems

-

High reliability in harsh operating environments

-

Comprehensive testing to guarantee performance and long-term stability

Why Choose Multilayer PCBs for Medical Device Applications?

Multilayer printed circuit boards enable complex circuitry in compact designs, providing enhanced performance for high-speed, high-frequency, and high-power applications. They are widely used in advanced medical devices that require signal stability, precision, and reliability.

Ring PCB’s Manufacturing Strengths

-

17 Years of Expertise – Extensive experience in multilayer PCB manufacturing and lamination processes

-

Fully Integrated Factory – PCB fabrication, SMT assembly, and testing under one roof

-

Strict Quality Control – 100% E-testing, AOI inspection, and functional testing

-

Flexible Order Capability – Prototype to mass production with consistent quality

-

Custom PCB Solutions – Based on customer-provided Gerber files, BOM, and drawings

-

Certified Manufacturer – UL, ISO9001, ISO14001, ISO13485, IATF16949

Common Technical Specifications – Multilayer PCB & PCBA

| Parameter | Specification |

|---|---|

| PCB Layers | 4–48 Layers |

| Base Materials | FR4, High-Tg FR4, Aluminum, Rogers, Polyimide |

| Board Thickness | 0.8 mm – 5.0 mm |

| Copper Thickness | 1 oz – 6 oz |

| Min. Line Width / Spacing | 3 mil / 3 mil |

| Min. Hole Size | 0.15 mm |

| Surface Finish | HASL, ENIG, Immersion Silver, OSP |

| Solder Mask Colors | Green, Blue, Black, White, Red |

| Operating Temperature | -40°C to +130°C |

| Testing Methods | AOI, ICT, X-Ray, Flying Probe, Functional Testing |

| Assembly Type | SMT, Through-hole, Mixed Assembly |

| Turnkey Option | Full Turnkey PCB Assembly Available |

Why Choose Ring PCB?

-

17 Years of PCB & PCBA Manufacturing Experience

-

Self-Owned Factories in Shenzhen & Zhuhai

-

Flexible Orders: Prototypes to High-Volume Production

-

Products Exported to 50+ Countries

-

Full Turnkey EMS Solutions

-

Long-Term Customer Partnerships Based on Quality and Trust

Closing CTA

Whether you need multilayer PCB prototyping, SMT assembly for medical devices, or full-scale EMS production, Ring PCB is your reliable manufacturing partner in China.

Contact Us

📧 Email: rfq@ringpcb.com