| Place Of Origin: | Shenzhen, China | Certification: | ISO9001, ISO14001, ISO13485, And IATF16949 |

| Type: | Industrial SFF Computer Motherboard PCBA | PCB Material: | High-Tg FR-4 (Tg ≥ 150°C), Or Rogers/PTFE For High-frequency Applications |

| Number Of Layers: | 4-10 Layers (common: 4/6/8 Layers For Complex Signal Routing In Industrial Applications) | Board Thickness: | 1.0 Mm - 2.0 Mm (standard: 1.6 Mm); Reinforced Thickness For Rugged Environments |

| Copper Thickness: | 1-2 Oz (35-70 μm); 2+ Oz For High-current Applications (e.g., Power Supply Traces) | Surface Finishes: | ENIG (Electroless Nickel Immersion Gold), HASL (Hot Air Solder Leveling), OSP (Organic Solderability Preservative) |

| Certifications: | IPC, RoHS, UL, ISO9001, ISO14001,ISO13485,IATF16949 | Testing And Inspection: | Automated Optical Inspection (AOI), X-ray Inspection |

| Other Service: | We Can Help With The Procurement Of Electronic Components On Behalf Of Customers. | Packaging Details: | Vacuum packing+Cardboard packing case |

| Supply Ability: | 50000㎡per week | ||

| Highlight: | Industrial Control PCB manufacturing, Double Power PCBA services, Turnkey PCBA for industrial | ||

Product Description

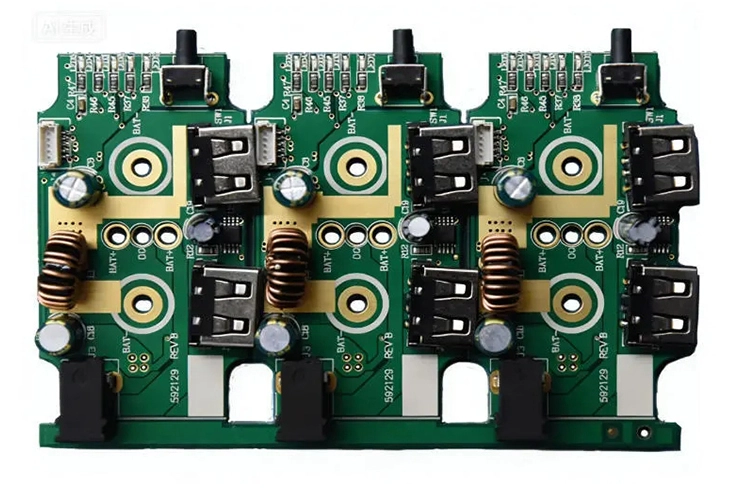

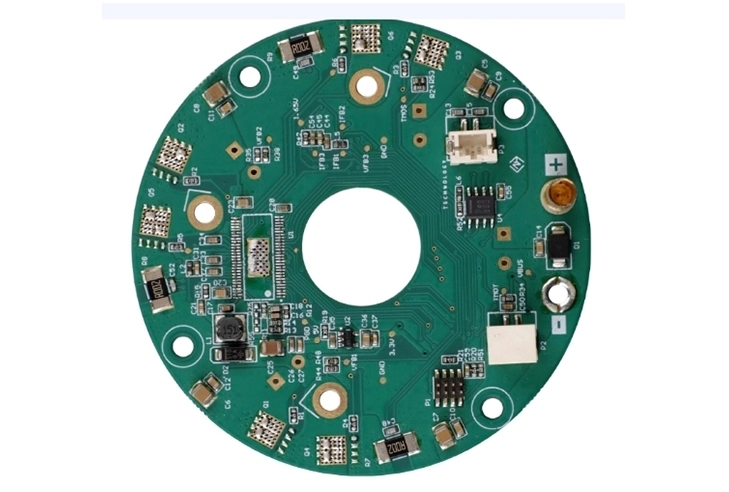

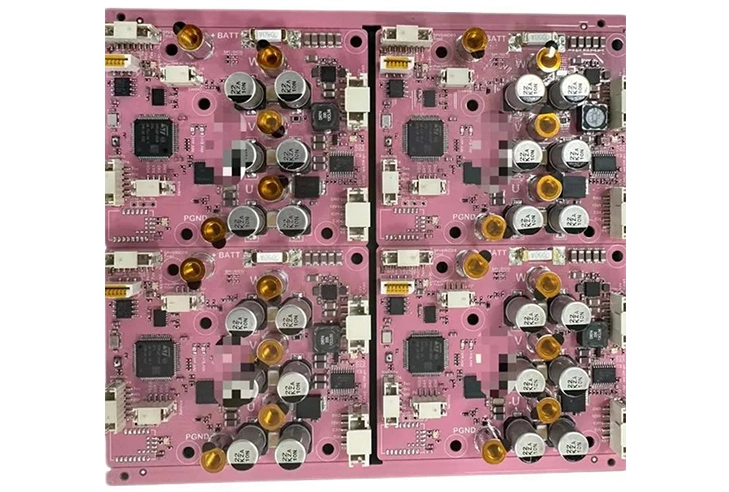

Ring PCB – Double Power Board for Industrial Control PCB with Full Turnkey Assembly Solutions

Reliable Dual Power Supply PCB Manufacturing & One-Stop Turnkey PCB Assembly Services for Industrial Control Applications.

Definition of Double Power Board for Industrial Control PCB

A Double Power Board for Industrial Control PCB is a specialized printed circuit board designed with dual independent power supply inputs to ensure uninterrupted and stable operation in industrial systems.

Also referred to as a dual power supply PCB or redundant power control board, this solution enables automatic switching between primary and backup power sources in the event of voltage fluctuation or power failure.

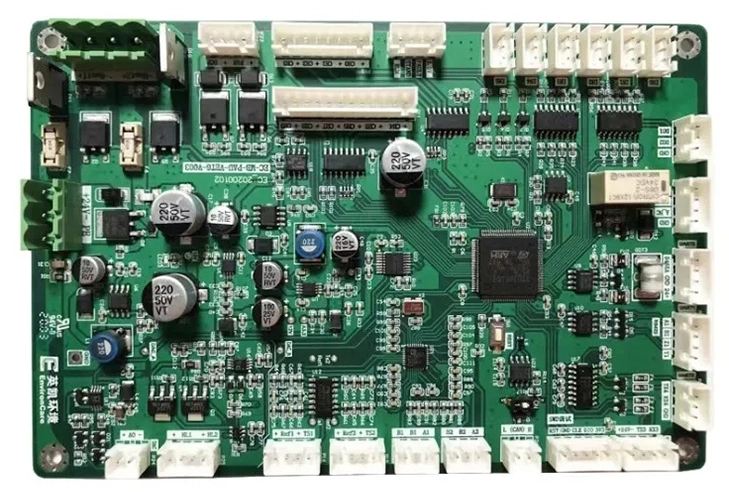

In industrial automation environments where system uptime is critical, double power industrial control PCBs are widely applied in:

-

PLC control systems

-

Factory automation equipment

-

Industrial controllers

-

Power management units

-

Mission-critical industrial applications

This design effectively minimizes downtime and enhances overall system reliability.

Product Features and Advantages

1. High Reliability & Power Redundancy

The core advantage of a double power industrial control PCB lies in its redundant power architecture.

With dual independent power inputs, the board maintains continuous operation even during power instability, significantly reducing unexpected shutdown risks.

2. Designed for Harsh Industrial Environments

Unlike consumer electronics, industrial systems demand higher durability.

Our industrial control PCBs are engineered for:

-

Wide operating temperature ranges

-

Strong resistance to EMI / ESD interference

-

Long-term continuous and stable operation

These features make the dual power supply PCB ideal for industrial control cabinets and automation systems.

3. Flexible Customization for Multiple Industries

Different industries have varying power and safety requirements.

Ring PCB offers fully customized PCB & PCBA solutions, adapting the double power board to applications including:

-

Industrial automation systems

-

Power & energy control equipment

-

Telecommunications infrastructure

-

Security and access control systems

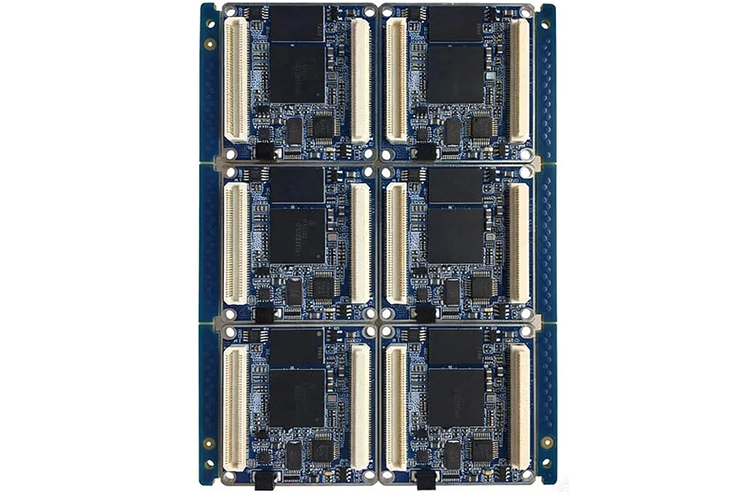

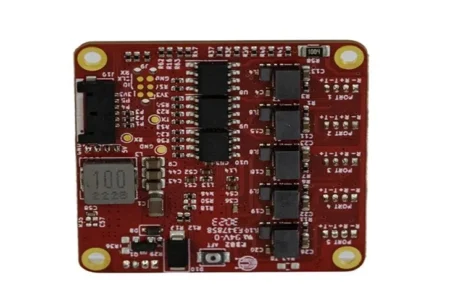

Rapid Prototyping & Mass Production Capability

Ring PCB has successfully solved the technical challenges associated with industrial dual power PCBA design and manufacturing.

-

Fast prototyping: 3–7 days

-

Small-batch & mass production supported

-

Customized PCBA based on schematics, BOM, or technical requirements

Typical Technical Parameters of a Double Power Board

| Parameter | Typical Specification |

|---|---|

| PCB Type | Industrial Control PCB |

| Power Input | Dual Power Input (AC/DC or DC/DC) |

| Power Redundancy | Automatic switching (Main / Backup) |

| PCB Layers | 2 – 6 Layers |

| Base Material | FR-4 / High-Tg FR-4 |

| Copper Thickness | 1 – 3 oz (Customizable) |

| Surface Finish | ENIG / OSP / Lead-Free HASL |

| Operating Temperature | -40°C to +85°C |

| Assembly Type | SMT + THT Mixed Assembly |

| Quality Standard | IPC Class 2 / IPC Class 3 |

| Typical Applications | PLC, Automation Systems, Power Control Units |

Why Choose Ring PCB for Industrial Control PCBA?

At Ring PCB, we don’t just manufacture products — we deliver reliable industrial solutions.

With complete PCB fabrication, PCB assembly, and turnkey PCBA services, we help customers reduce cost, shorten lead time, and improve product stability.

17 Years of Excellence | Self-Owned Factory | End-to-End Technical Support

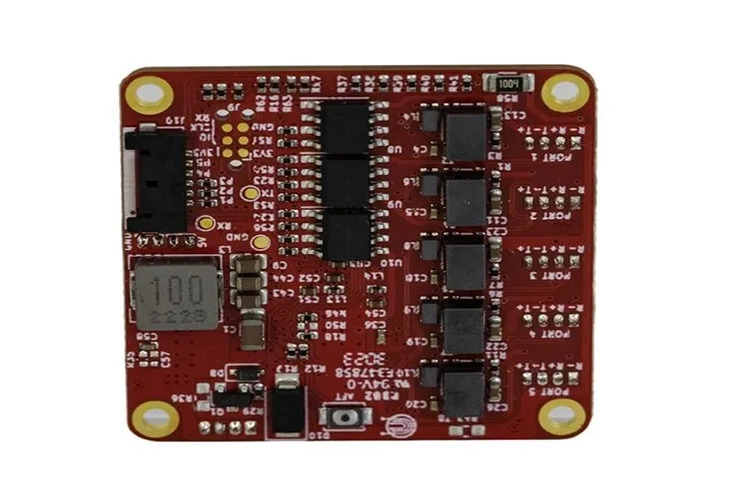

Core Advantage 1: Advanced Engineering for Precision PCB Manufacturing

-

High-density stack-up: 2–48 layers, blind & buried vias

-

Minimum trace/spacing: 3/3 mil, impedance tolerance ±7%

-

Ideal for industrial control, medical devices, automotive electronics, and 5G applications

-

IPC-6012 Class 3 manufacturing standards

Core Advantage 2: Integrated PCBA Services | One-Stop Turnkey Solutions

✓ PCB fabrication + component sourcing + SMT assembly + functional testing

✓ DFM / DFA optimization to reduce design risks and BOM costs

✓ AOI, X-ray inspection, and 100% functional testing

Core Advantage 3: Self-Owned Factory with Full Supply Chain Control

✓ Vertical integration from raw materials to final testing

✓ Triple quality assurance: AOI + impedance testing + thermal cycling

✓ Defect rate < 0.2% (industry average <1%)

✓ Certifications: ISO9001, IATF16949, RoHS

Contact Us

📧 Email: rfq@ringpcb.com