| Place Of Origin: | Shenzhen, China | Certification: | ISO9001, ISO14001, ISO13485, and IATF16949. |

| Type: | Communication PCBA | Board Thickness: | Usually 0.8 - 2.4mm |

| Line Width/Spacing: | Commonly 0.1 - 0.3mm / 0.1 - 0.3mm | Surface Finish: | ENIG (Electroless Nickel Immersion Gold), HASL (Hot - Air Solder Leveling), Etc. |

| Operating Temperature: | -40°C - 85°C | Signal Frequency: | Ranges From Low - Frequency (kHz) To High - Frequency (GHz) Depending On Application |

| Power Consumption: | Varies Widely Based On Components, E.g., A Few MW To Several W | Certifications: | IPC, RoHS, UL, ISO9001, ISO14001,ISO13485,IATF16949 |

| Testing And Inspection: | Automated Optical Inspection (AOI), X-ray Inspection | Assembly Accuracy: | Tolerance Within ±0.05 - 0.1mm For Component Placement |

| Insulation Resistance: | ≥1000MΩ | Other Service: | We Can Help With The Procurement Of Electronic Components On Behalf Of Customers. |

| Application Areas: | Are Used In A Wide Array Of Devices, Including: Base Stations For Mobile Networks. Routers And Modems For Internet Connectivity. Satellite Communication Systems For Global Coverage. Optical Networking Equipment For High-speed Data Transfer. | Packaging Details: | Vacuum packing+Cardboard packing case |

| Supply Ability: | 50000㎡per week | ||

| Highlight: | PCBA for communication device, communication device PCB manufacturer, fast prototype PCBA production | ||

Product Overview

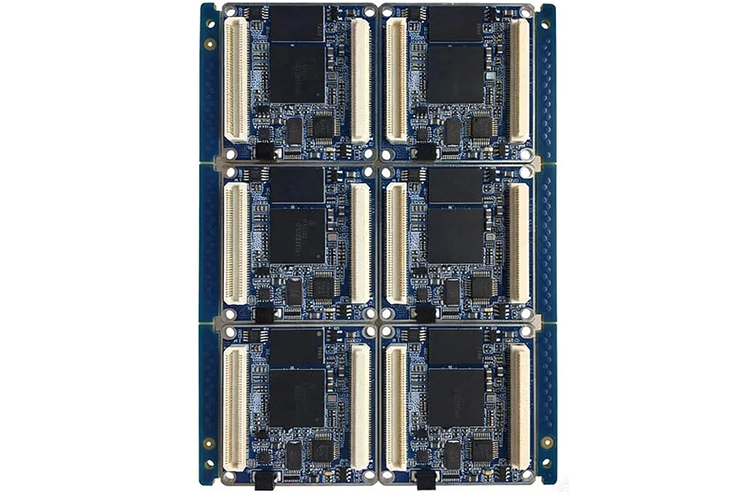

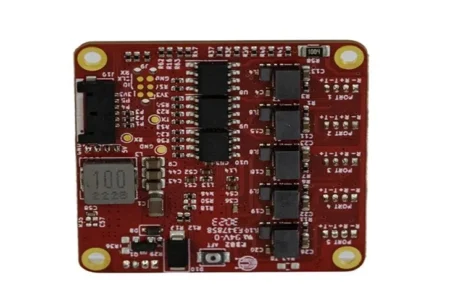

One-Stop PCB & PCBA Solutions for Communication Equipment

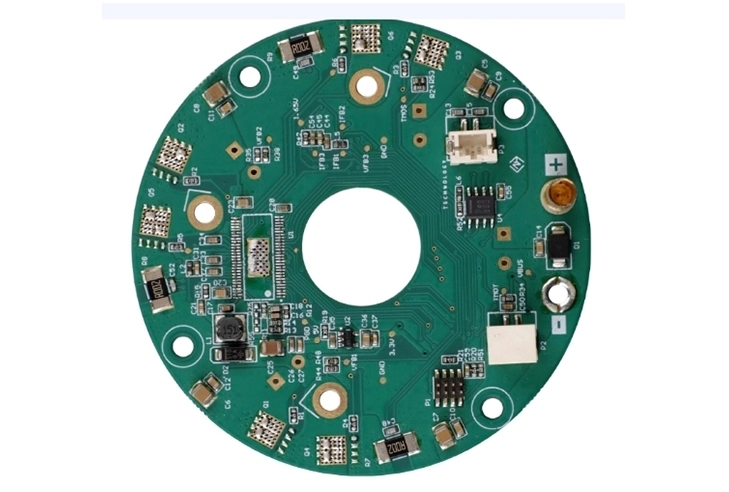

Ring PCB is a professional PCBA manufacturer for communication devices, providing end-to-end PCB fabrication and PCB assembly services — from fast prototyping to mass production.

With 17 years of manufacturing experience and a self-owned factory in Shenzhen, we support global customers with high-reliability, high-frequency communication PCBAs.

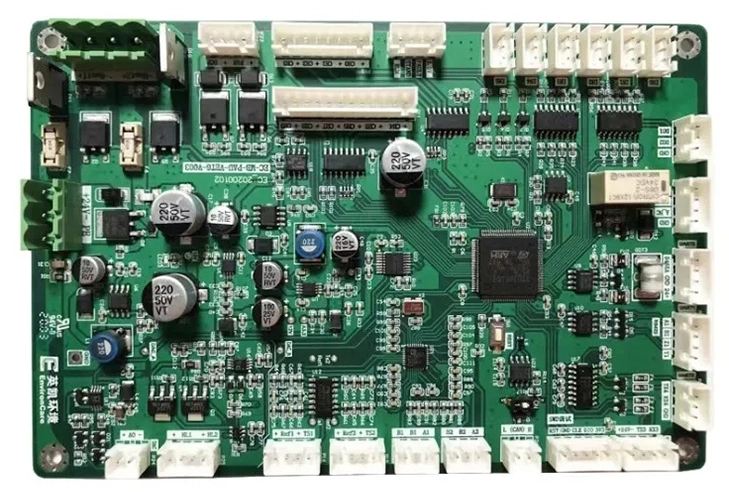

Our services cover routers, base stations, wireless modules, IoT devices, optical communication equipment, and other data transmission systems requiring stable signal integrity and long-term reliability.

What Is Communication PCBA?

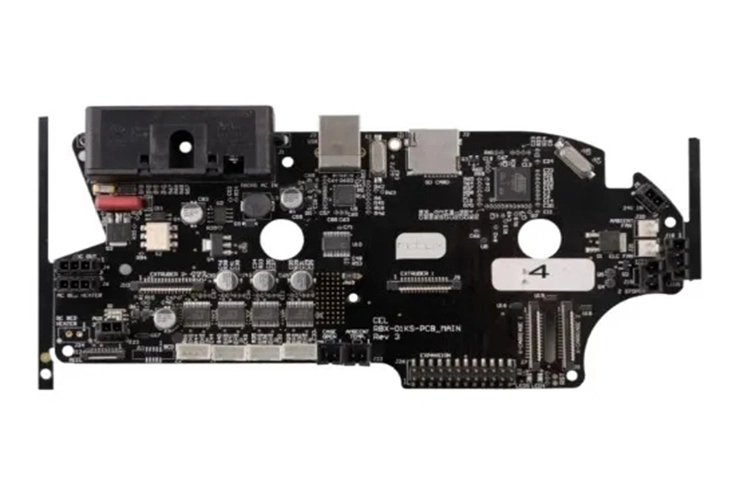

Communication PCBA (Printed Circuit Board Assembly) is a fully assembled PCB designed for signal transmission, processing, and reception in communication systems.

It integrates:

-

High-speed processors

-

RF and communication chips

-

Power management circuits

-

Connectors and interfaces

These assemblies form the core hardware platform of modern wired and wireless communication devices.

Key Characteristics of Communication PCBAs

High-Frequency Performance

Designed for GHz-level signal transmission with low loss and low interference.

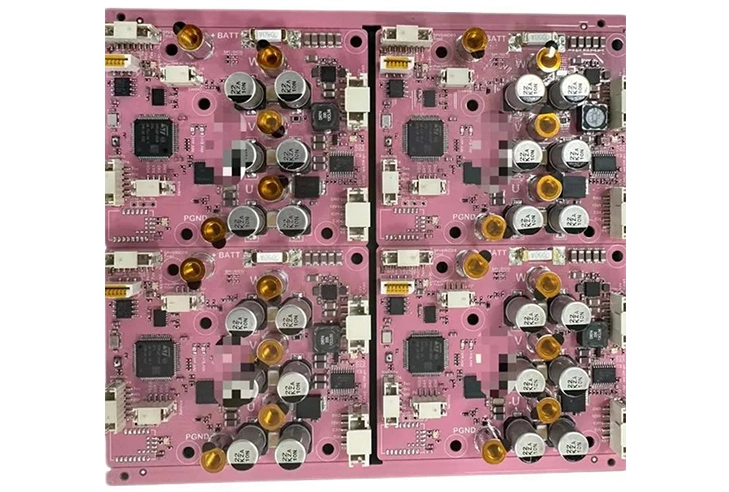

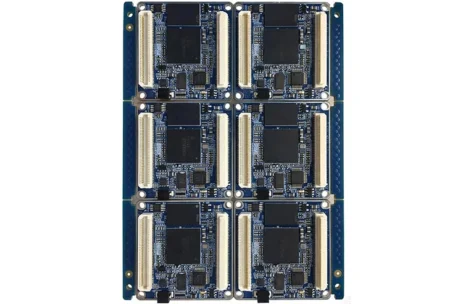

High-Density & Miniaturization

HDI technology supports compact layouts, fine-pitch components, and multilayer designs.

Long-Term Reliability

Built to operate 24/7 under thermal stress, vibration, and complex environments.

Functional Integration

Combines data processing, modulation, demodulation, and protocol execution on a single board.

Flexible Customization

PCB stack-up, materials, impedance, and power design tailored to your application.

Communication PCBA Applications

Our PCBAs are widely used in:

-

Mobile network base stations

-

Routers & modems

-

Optical communication equipment

-

Satellite communication systems

-

IoT & smart devices

Manufacturing Challenges & Ring PCB Solutions

1. High-Speed Signal Integrity

Solution:

-

Controlled impedance PCB design

-

Low-loss materials (Rogers, Isola, Nelco)

-

TDR and impedance testing

2. Thermal Management

Solution:

-

Thermal vias & copper planes

-

Aluminum-based PCBs

-

8-stage lead-free reflow soldering

3. HDI & Multilayer Complexity

Solution:

-

Blind/buried vias & microvias

-

Up to 48-layer PCB manufacturing

-

Fine-line & fine-pitch SMT assembly

4. Environmental Resistance

Solution:

-

Conformal coating & encapsulation

-

Thermal shock & environmental testing

5. Power Efficiency

Solution:

-

Optimized copper thickness & routing

-

Efficient power management layouts

6. Regulatory Compliance

Solution:

-

RoHS & REACH compliant production

-

ISO9001 & IATF16949 certified factory

Common Technical Parameters

| Parameter | Specification |

|---|---|

| Board Thickness | 0.8 – 2.4 mm |

| Min Line Width / Spacing | 0.1 / 0.1 mm |

| PCB Layers | 2 – 48 Layers |

| Surface Finish | ENIG, HASL, OSP |

| Operating Temperature | -40°C to +85°C |

| Signal Frequency | kHz – GHz |

| Assembly Accuracy | ±0.05 – 0.1 mm |

| Insulation Resistance | ≥1000 MΩ |

| Assembly Type | SMT / THT / Mixed |

Why Choose Ring PCB?

17 Years of Industry Experience

Trusted by over 20,000 global customers.

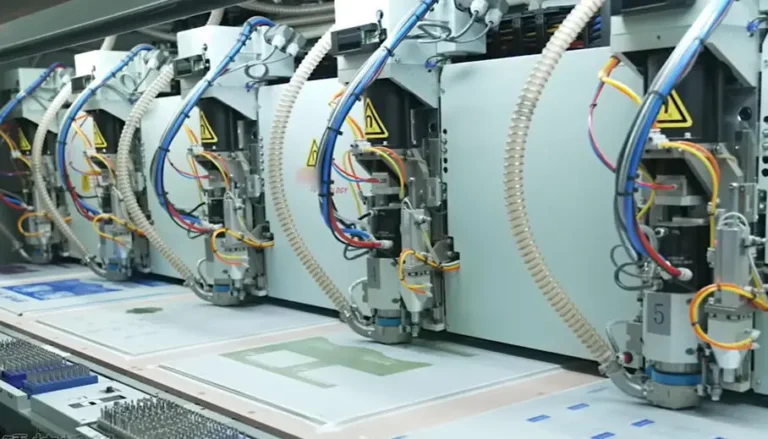

One-Stop Turnkey PCBA Service

PCB fabrication + component sourcing + SMT/DIP assembly + testing.

Advanced Manufacturing Capability

LDI exposure, vacuum lamination, AOI, X-ray inspection, flying probe testing.

Self-Owned Factory & Full Process Control

Stable quality, fast delivery, competitive pricing.

Global Certifications

ISO9001, IATF16949, RoHS compliant.

Important Notice

-

All products are customized services. Please contact us before ordering.

-

Product images are real; minor color differences may occur due to lighting and display settings.

Contact Us

📧 Email: rfq@ringpcb.com